Insights from Empire Building Challenge

Improved engineering design means and methods are needed to enable and speed adoption of low-carbon retrofit technologies. High performance, low-carbon heating and cooling systems are widely available but are underutilized in the United States due to a variety of misconceptions and a lack of knowledge around thermal system interactions. Few practicing engineers prioritize recycling heat and limiting heat loss. Decarbonization requires upgrading and adapting energy distribution systems originally designed to operate with high temperature combustion to integrate with electric and renewable thermal energy systems. The engineering design industry can use a thinking framework like Resource Efficient Decarbonization (RED) to deliver projects that achieve more effective decarbonization.

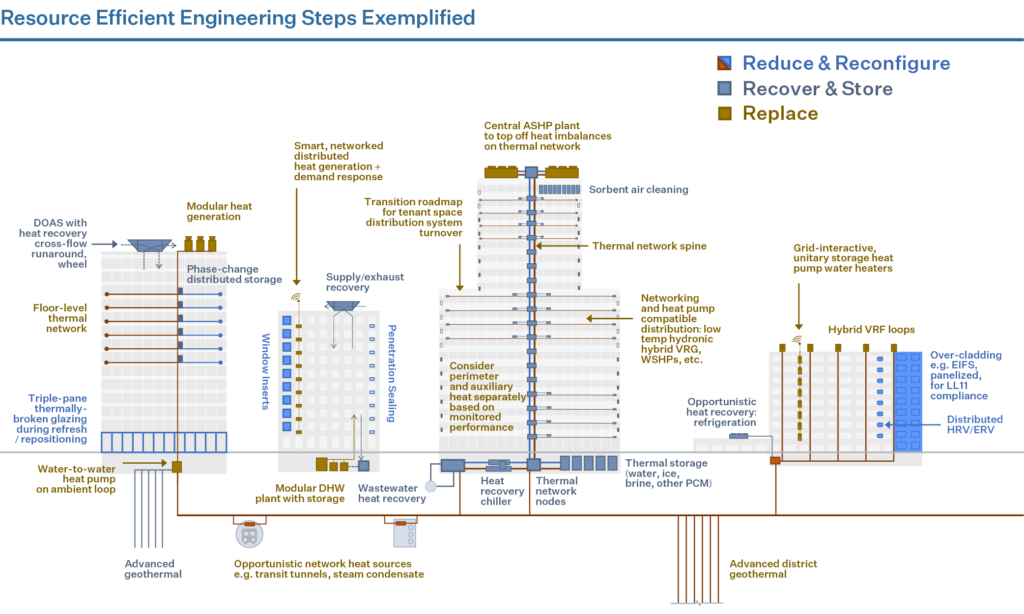

This framework emerges from the Empire Building Challenge through continued collaboration among real estate partners, industry-leading engineering consultants, and NYSERDA. RED is a strategy that can help alleviate space constraints, optimize peak thermal capacity, increase operational efficiencies, utilize waste heat, and reduce the need for oversized electric thermal energy systems, creating retrofit cost compression. While RED is tailored to tall buildings in cold-climate regions, the framework can be applied across a wide array of building types, vintages, and systems. The approach incorporates strategic capital planning, an integrated design process, and an incremental, network-oriented approach to deliver building heating, cooling, and ventilation that:

- Requires limited or no combustion,

- Enables carbon neutrality,

- Is highly efficient at low design temperatures and during extreme weather,

- Is highly resilient, demand conscious, and energy grid-interactive,

- Reduces thermal waste by capturing and recycling as many on-site or nearby thermal flows as possible, and

- Incorporates realistic and flexible implementation strategies by optimizing and scheduling phase-in of low-carbon retrofits competing with business-as-usual.

Decarbonization Framework

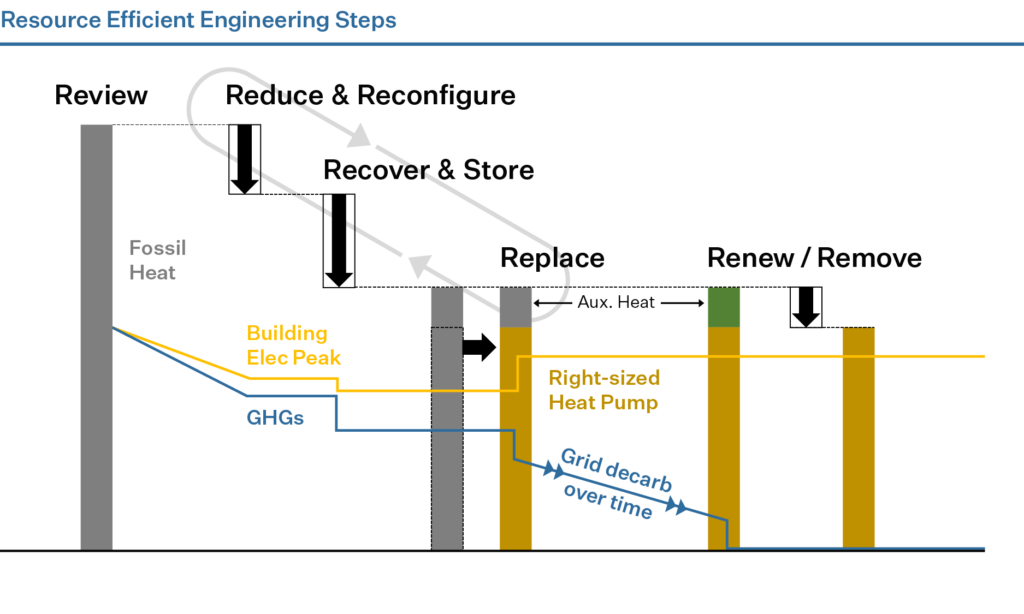

Resource Efficient Decarbonization focuses on implementing enabling steps that retain a future optionality as technology and policy evolves. This framework allows a building owner or manager to take action now, instead of waiting for better technology and potentially renewing a fossil-fueled powered energy system for another life cycle.

The figure below illustrates a conceptual framework for accomplishing these objectives and overcoming the barriers. Specific measures and sequencing will be highly bespoke for a given building, but engineers and their owner clients can use this bucketed framework to place actionable projects in context of an overarching decarbonization roadmap.

Step-by-Step Process to Advise Decarbonization Efforts

- Understanding a building’s fossil fuel use in detail is a critical first step. Make an effort to understand when, where, how, and why fossil fuels are being consumed at the building and under what outdoor temperature and weather conditions. Conduct a temperature BINS analysis to know how much fossil fuel is consumed during various temperature bands (typically in 5- or 10-degree increments) from design temperature up to the end of the heating season. Make an effort to understand cooling season usage patterns in detail. Go further and conduct an 8760 hour/year analysis or modeling effort to show building operation profiles with high granularity to advise targeted elimination of fossil fuel consumption.

- While electrification is desirable to combat climate change, energy efficiency is a critical component of decarbonization. Reducing heating and cooling loads across all weather conditions is a major early step to achieve RED.

- Identify the ways heat is being gained or lost. Hint: some places to look at are cooling towers, facades and windows, elevator machine rooms, through sewer connections, or at the ventilation exhaust system. Cooling towers operating in the winter are an obvious energy wasting activity. Seek solutions to reduce, recover, and recycle or reuse, and store this heat.

- After, or in parallel with the previous steps, begin to electrify the building heat load, starting with marginal “shoulder season” loads (spring and fall). Don’t force electric heating technology such as air source heat pumps to operate during conditions for which they weren’t designed. Optimize heat pump implementation through a “right sizing” thermal dispatch approach to avoid poor project economics and higher operating expenses. This means continuing to retain an auxiliary heating source for more extreme weather conditions until fossil fuels are ready to be fully eliminated. This approach provides owners time to identify the right peak period heating solution while allowing them to act early in driving down emissions. Emissions reduced sooner are more valuable than emissions reduced in the future.

- Remove connections to fossil fuels and meet decarbonization deadlines!

Take Actions with these Enabling Steps

Review

- Disaggregate time-of-use profiles to identify heat waste and recovery opportunities and to right-size equipment.

- Thermal dispatch strategy: layering heat capacity to optimize carbon reduction and project economics.

Reduce

- Repair, upgrade and refresh envelopes.

- Optimize controls.

Reconfigure

- Eliminate or reduce inefficient steam and forced air distribution.

- Create thermal networks and enable heat recovery.

- Lower supply temperatures to ranges of optimal heat pump performance.

- Segregate and cascade supply temperatures based on end-use.

Recover

- Simultaneous heating and cooling in different zones of building.

- Eliminate “free cooling” economizer modes.

- Exhaust heat recovery; absorbent air cleaning.

- Building wastewater heat recovery.

- Municipal wastewater heat recovery.

- Steam condensate.

- Refrigeration heat rejection.

- Other opportunistic heat recovery and heat networking.

Store

- Store rejected heat from daytime cooling for overnight heating.

- Store generated heat— centrally, distributed, or in the building’s thermal inertia.

- Deploy advanced urban geothermal and other district thermal networking solutions.

Building Systems Topologies

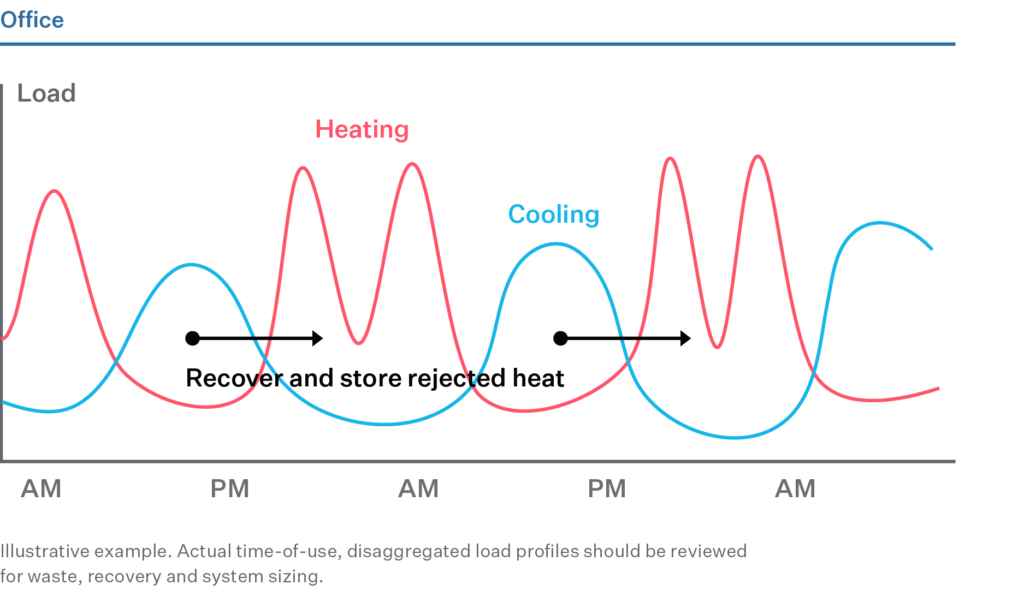

Commercial Office

Commercial office buildings offer significant heat recovery and storing opportunities due to simultaneous heating and cooling daily profiles. As a result, offices can heat themselves much of the year with heat recovery and storage. Example load profiles for typical heating and cooling days in a commercial office building are shown in the graph below.

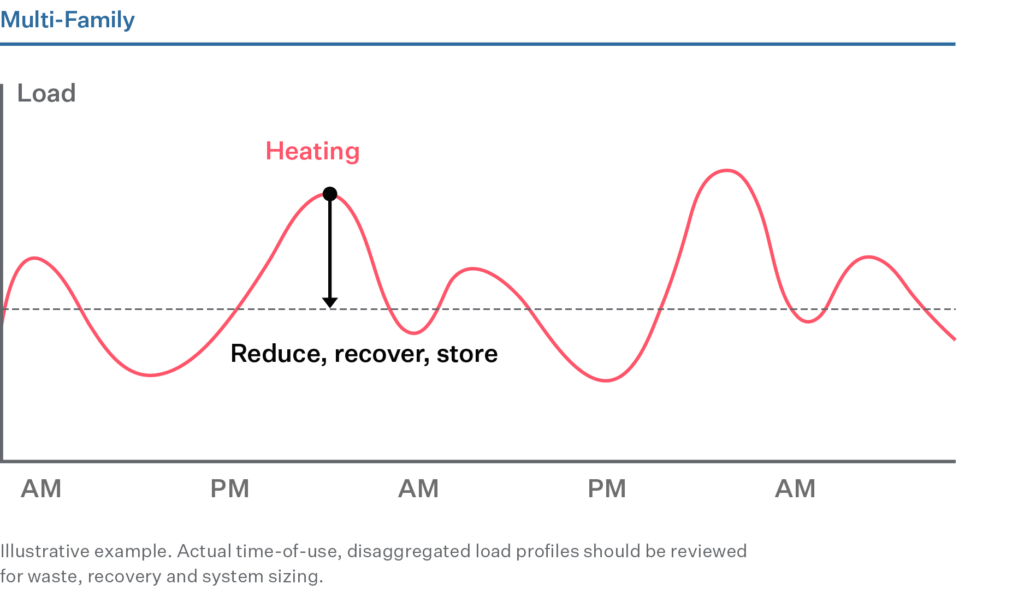

Multi-family

Multi-family buildings’ typical daily profiles show efficiency opportunities that can lower and flatten system peaks. This can be achieved by a variety of heat reduction, recovery, and storing strategies. Example load profiles for a typical heating day in a multifamily building are shown in the graph below.

Thermal Distribution Opportunities

The thermal energy network approach enables transaction of thermal energy to increase overall system efficiency and reduce wasted heat. The concept can be applied at the building level (with floor-by-floor heat exchange), to groups of buildings, to whole neighborhoods, or to cities. Below is an illustration of a whole-system, thermal network approach applied in an urban environment to supply clean heat in cold-climate tall buildings: