Charrette Overview

A charrette is a focused, collaborative convening of diverse stakeholders. In planning a building decarbonization project, charrettes are a powerful tool for establishing a holistic understanding of a building’s existing conditions and needs, aligning stakeholders, developing creative solutions, and accelerating the retrofit design process.

Context

While charrettes can be used within multiple contexts, this resource has been developed to support the review of a preliminary retrofit plan. The preliminary retrofit plan scope is developed based on existing building conditions, high-level energy data and calculations, as well as the team’s expertise and prior project experience. Having a charrette at this point in the process allows for early feedback about the retrofit scope and alignment with project goals. It provides an opportunity for collaborative problem-solving and the development of creative solutions, as multi-disciplinary stakeholders are brought together to iterate on the retrofit. More detailed energy and financial analysis will occur after the charrette and may drive scope change as the team uses results to optimize the retrofit.

Templates Overview

The following templates have been developed to reduce the effort required to include a charrette in retrofit planning and guide project teams through the charrette process. The format of the templates is intentionally basic so your organization(s)’ presentation format and logos can easily be added.

The templates are intended to be used by the design team to gather feedback and develop consensus from project stakeholders on the following topics:

- Project goals

- Retrofit triggers

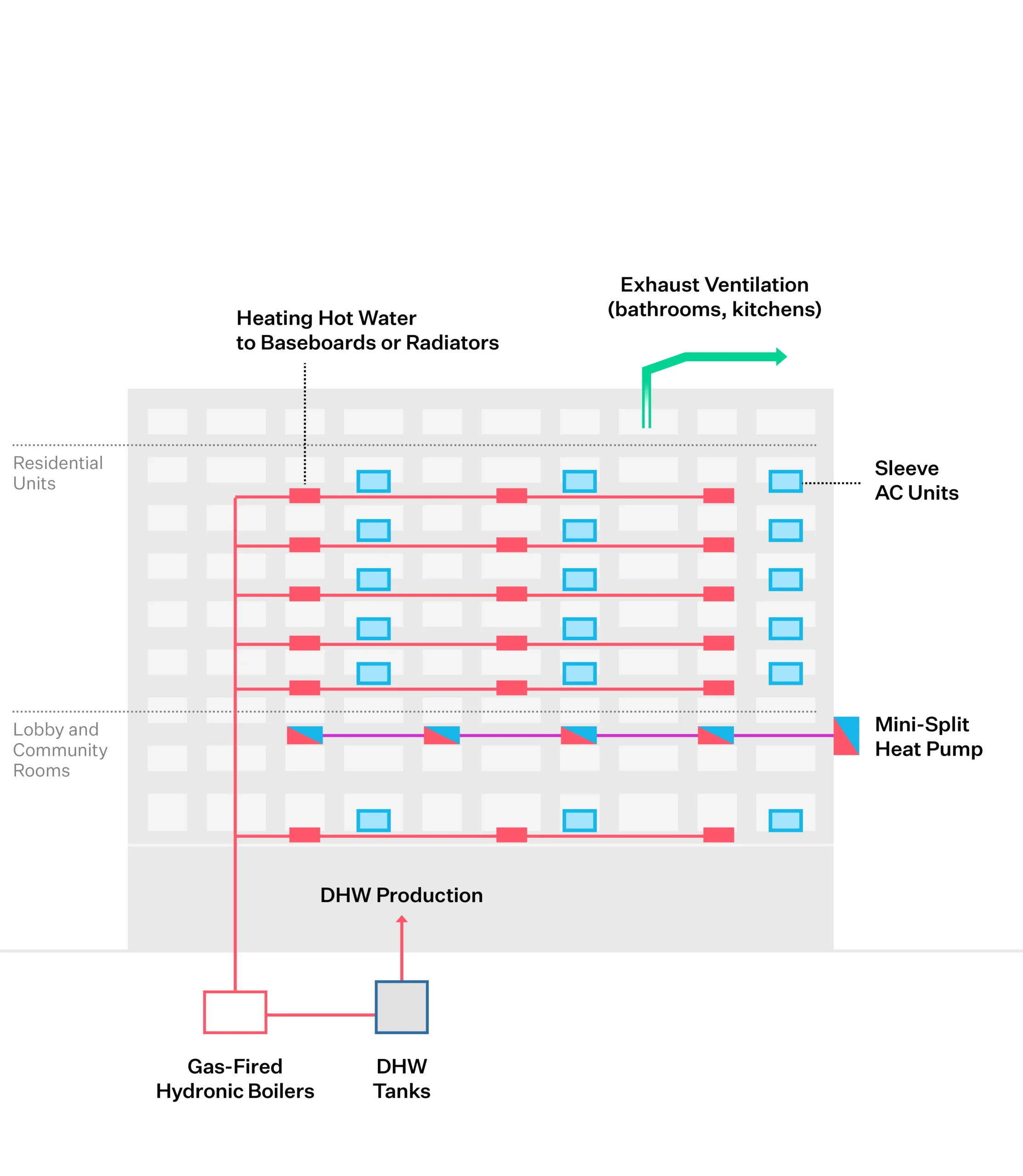

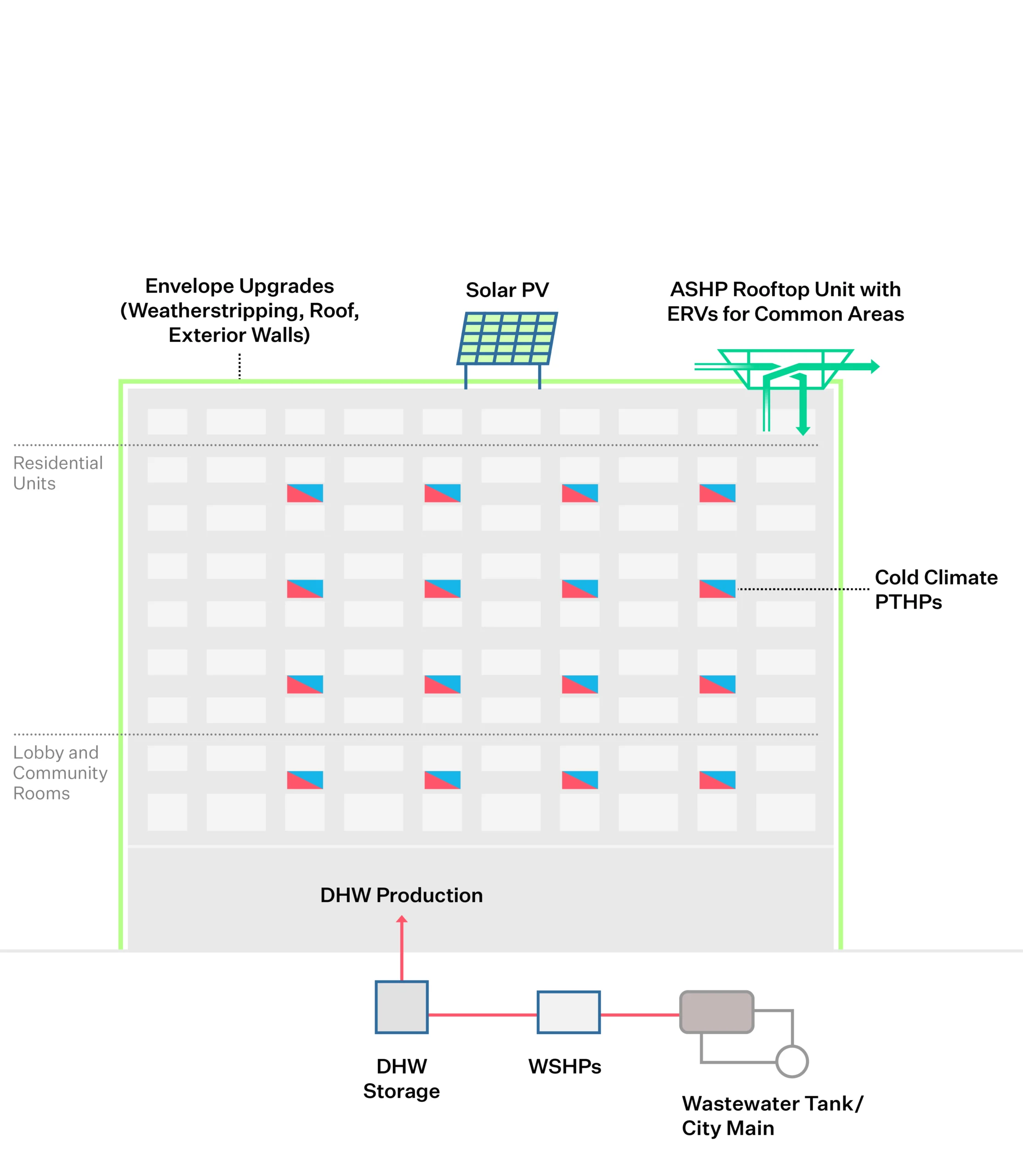

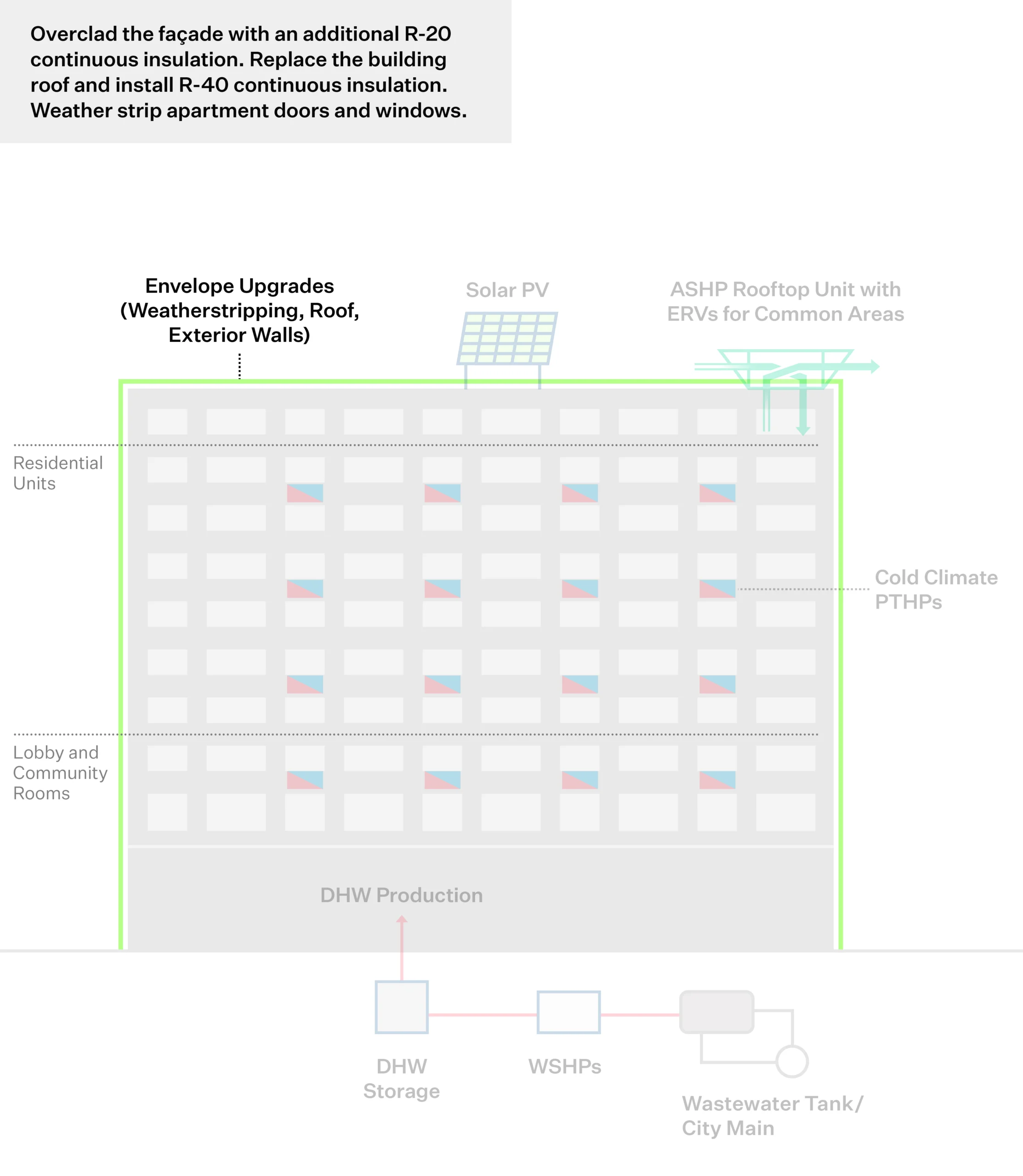

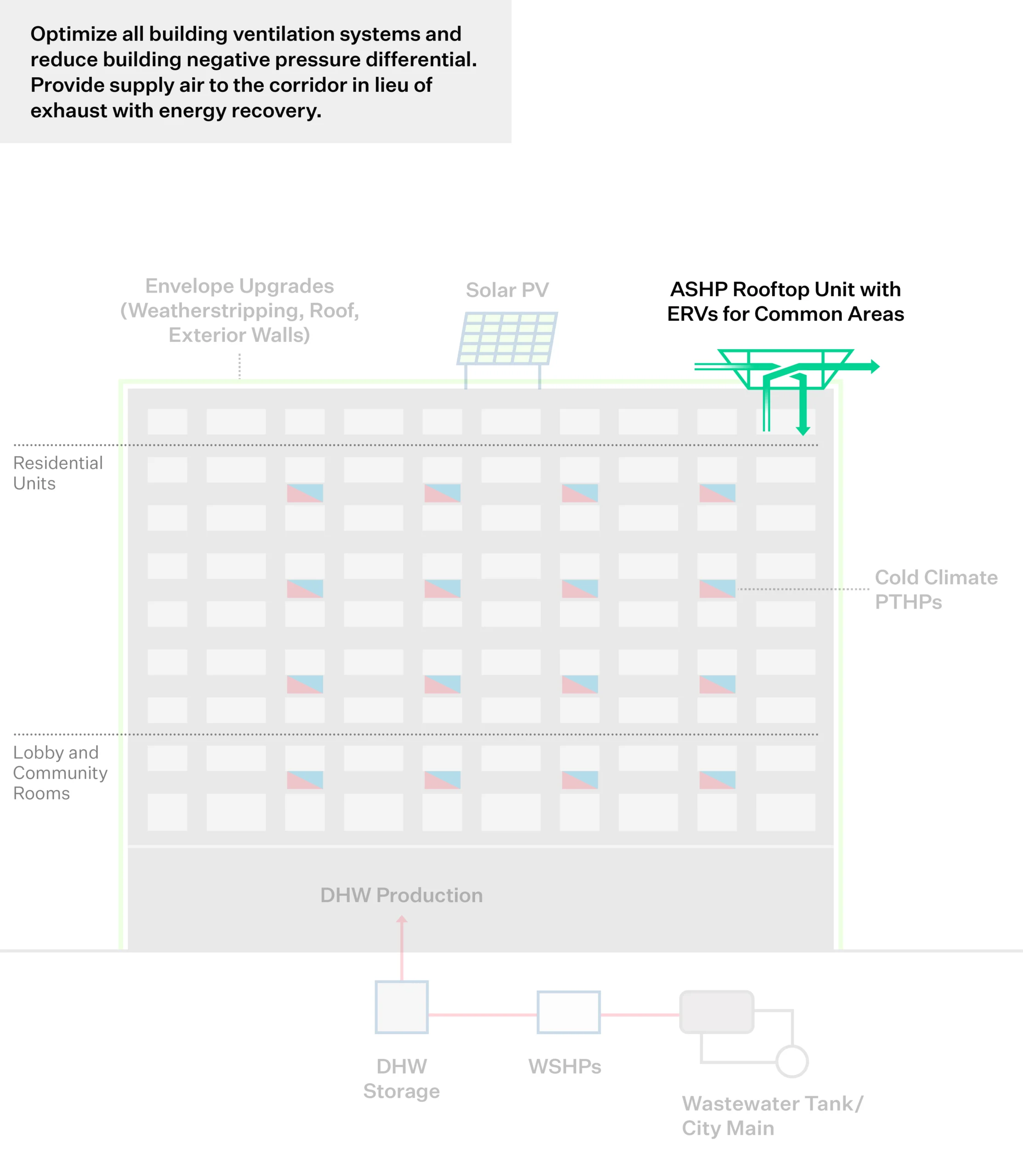

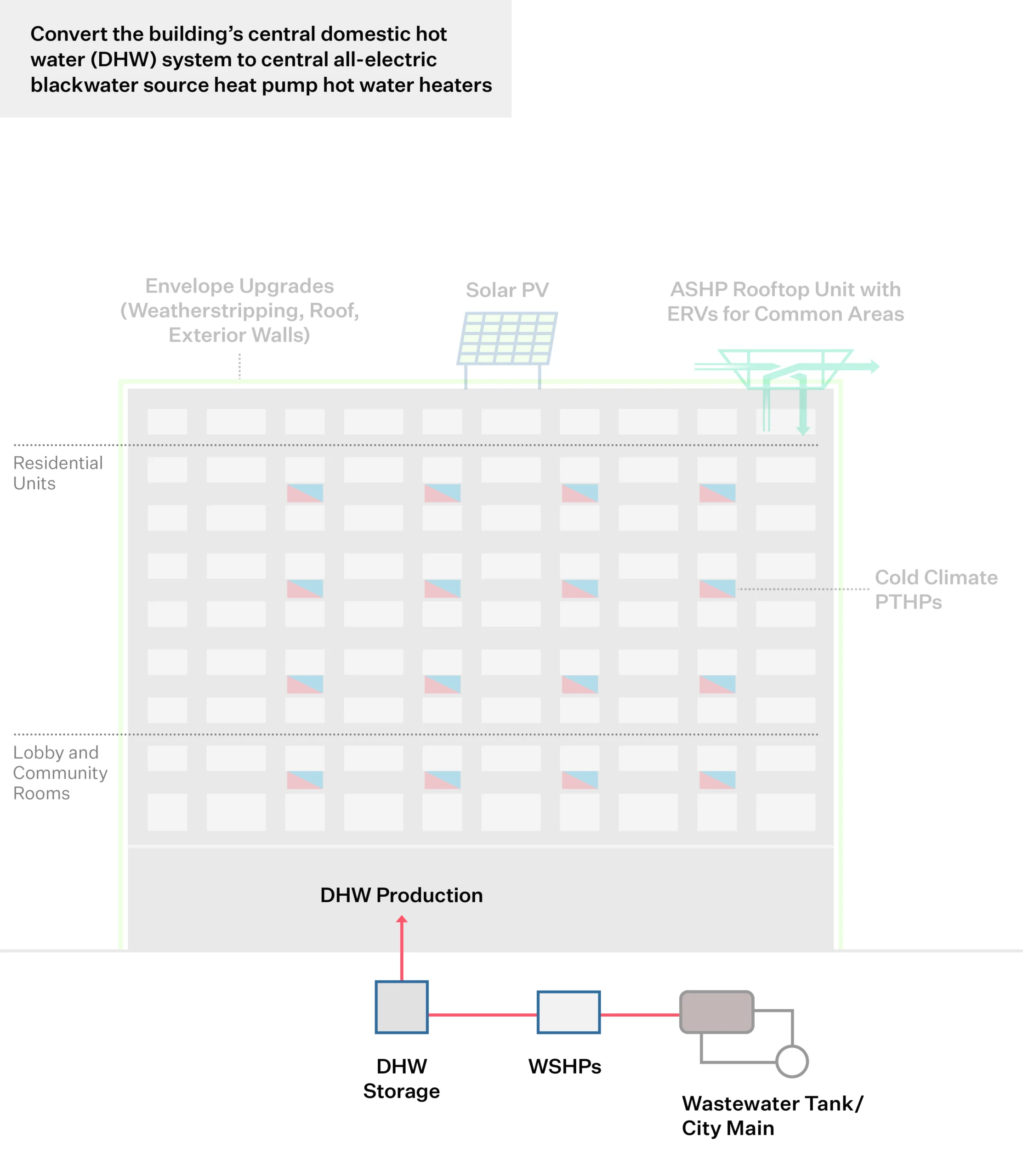

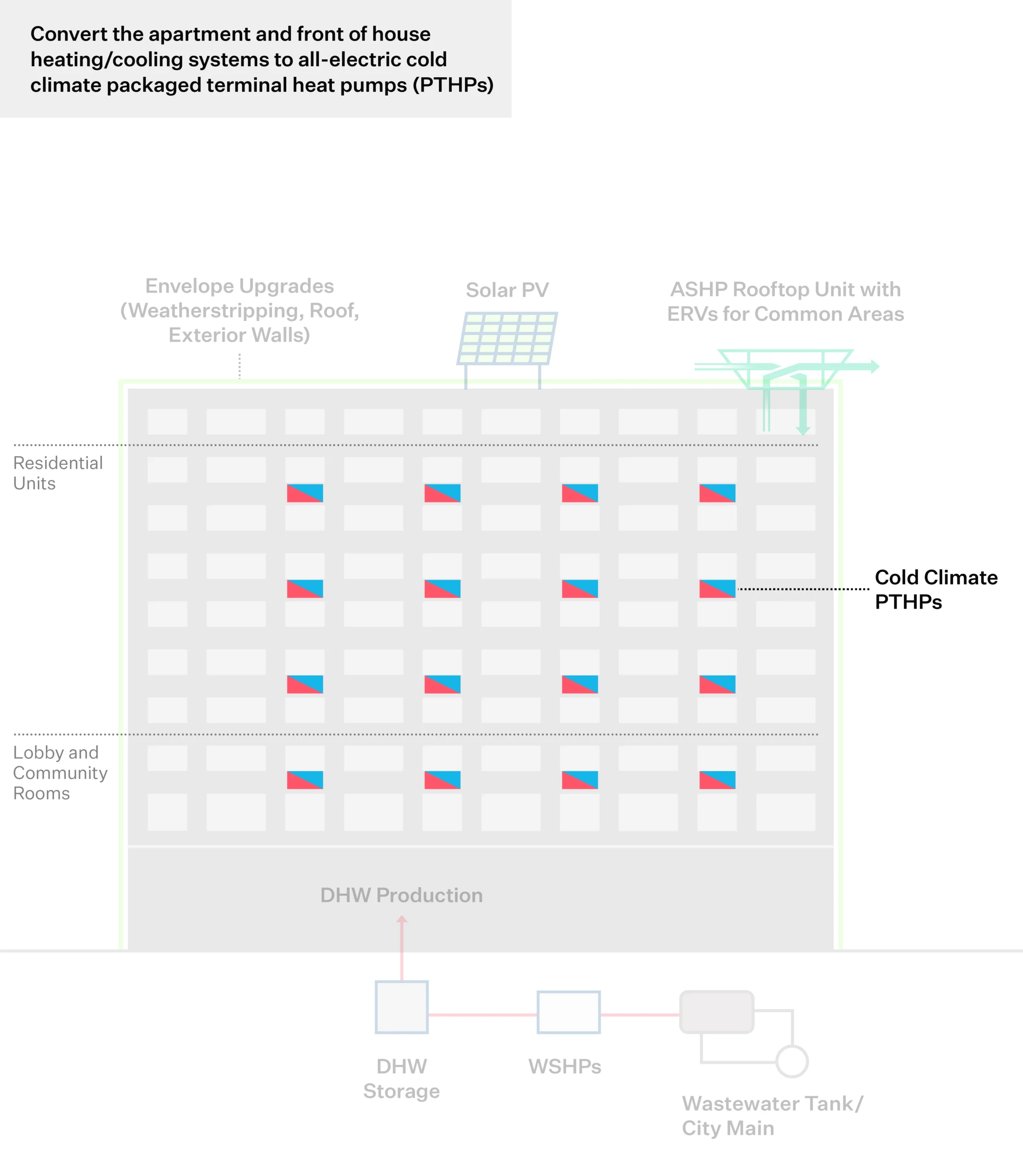

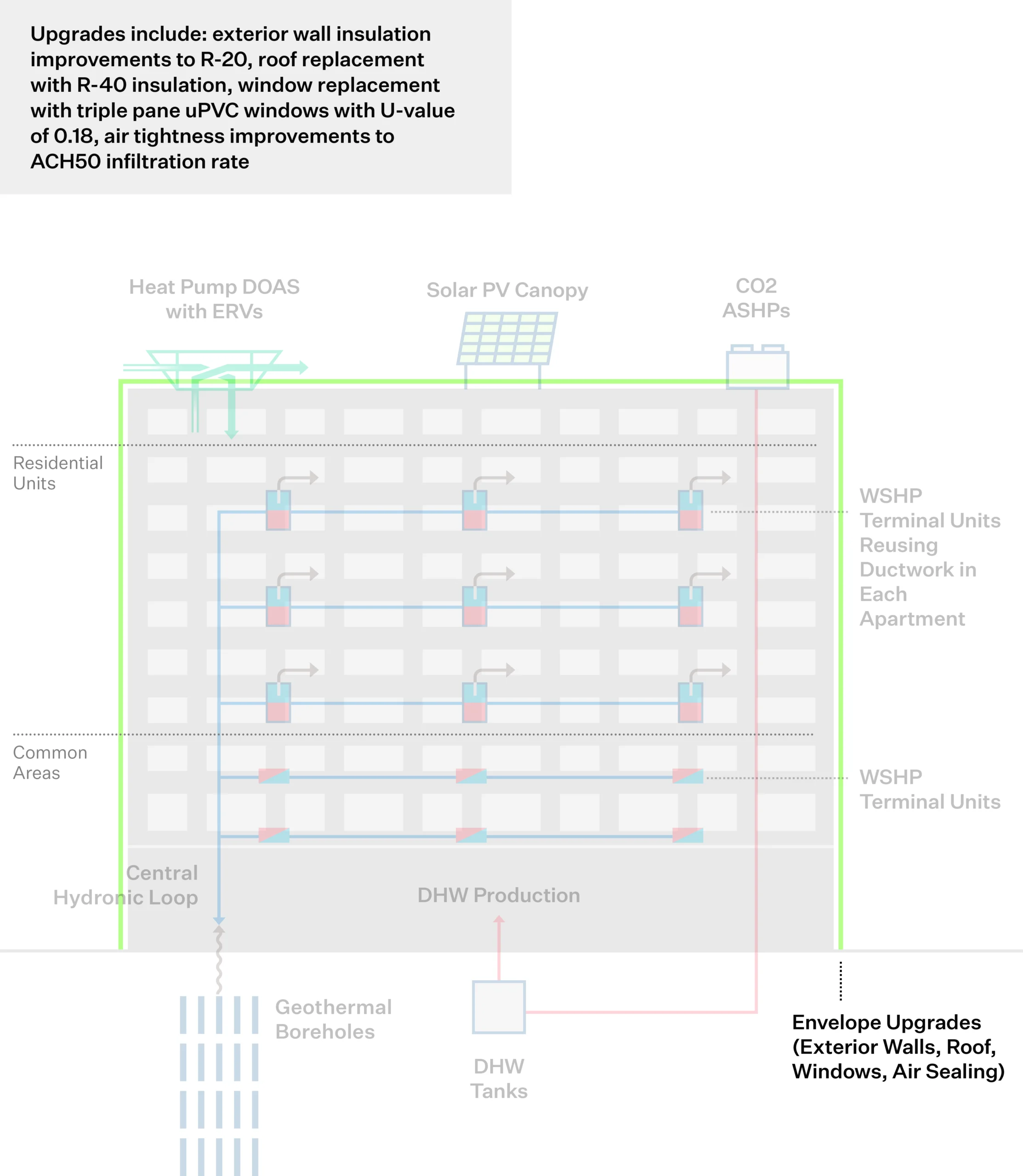

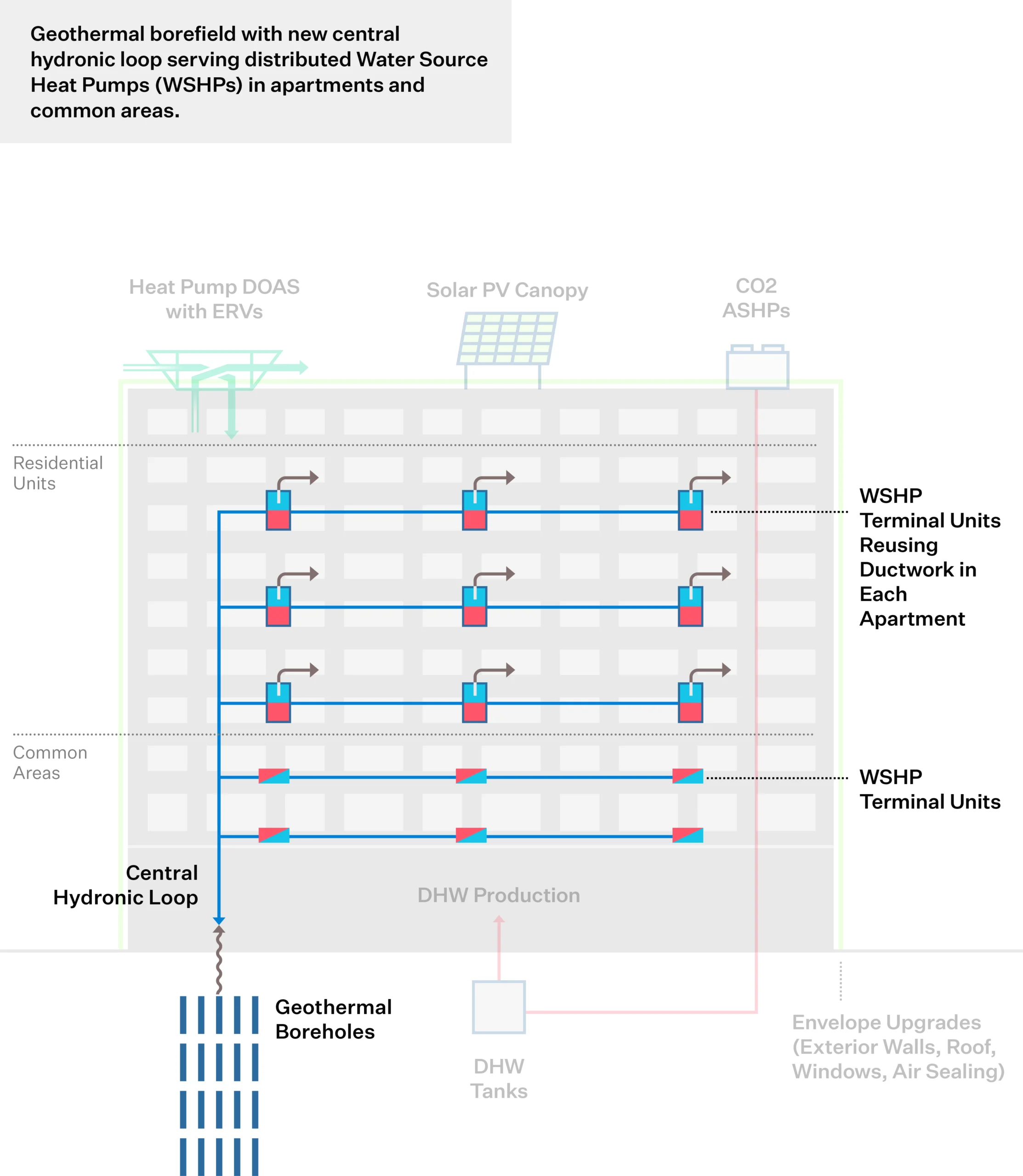

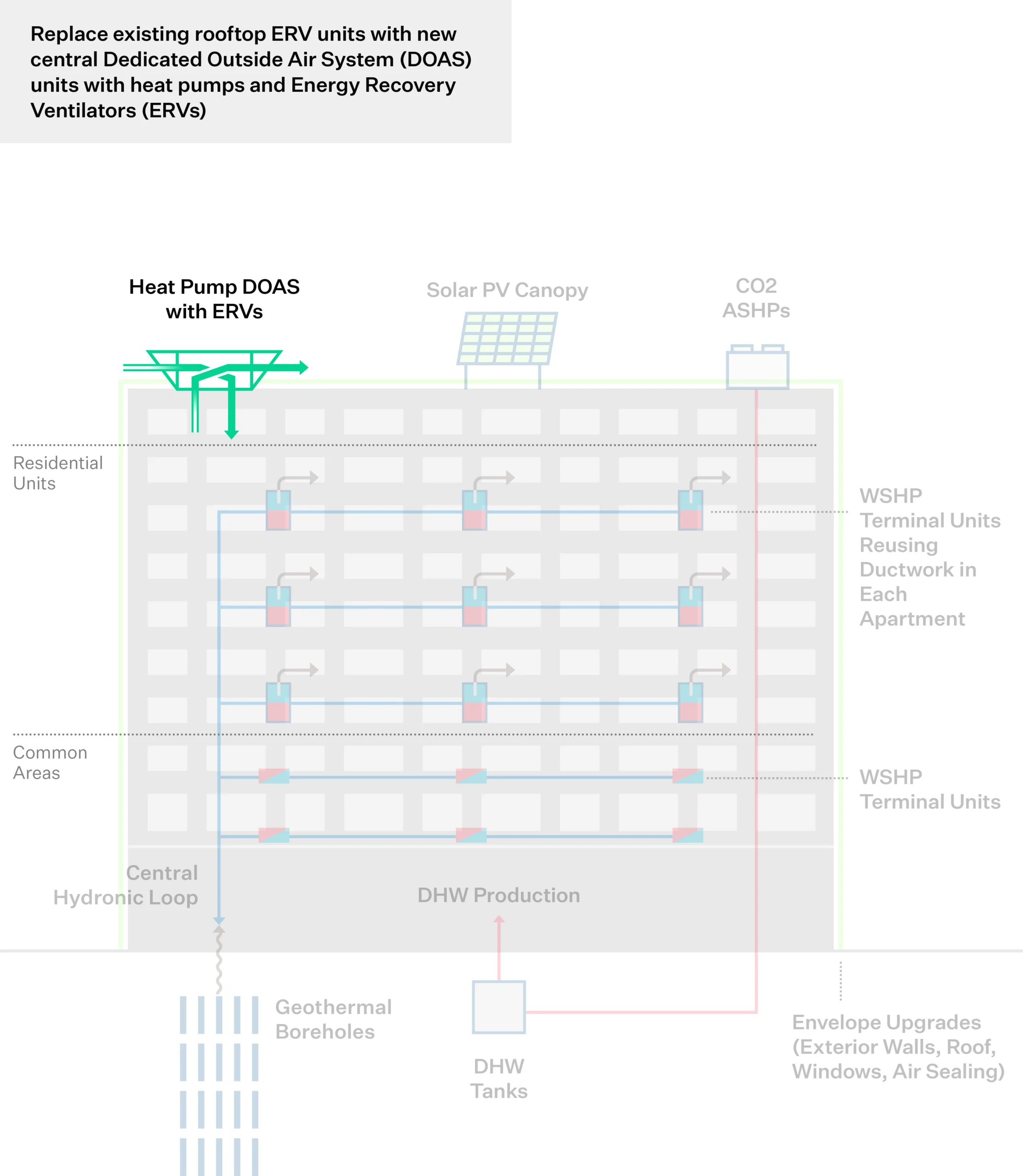

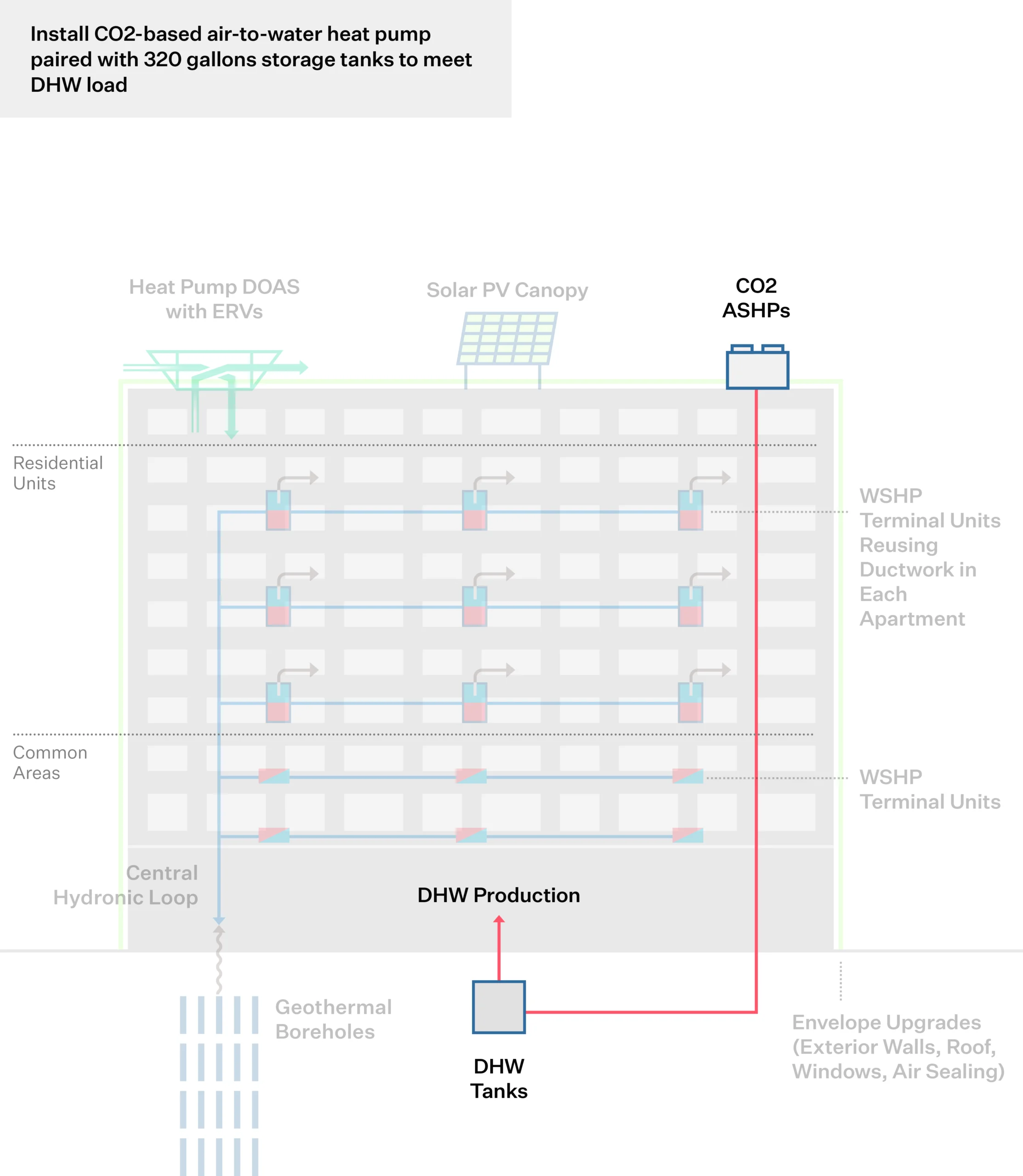

- Proposed retrofit plan

Three templates are available for download and are designed to work together. These include:

Pre-Read Template: Use this template to develop a project-specific pre-read document that can help inform the charrette discussion. This template offers a preset agenda for the charrette and provides space to clearly define project goals, trigger events, and a high-level summary of the retrofit plan. To maximize benefit from the charrette it is important that attendees arrive with a solid understanding of the information provided in the pre-read. Therefore, it is recommended the document remain as concise as possible and is sent to attendees with sufficient time for them to review.

Download the Pre-Read TemplateCharrette Presentation Template: This easily customizable slide deck template provides a framework and content to guide project teams through the charrette. The intended outcomes from the charrette are level setting stakeholders on the project’s status and plans, collecting feedback, and ideation.

Download the Presentation TemplatePost-Charrette Report Template: Use this template to capture outputs from the charrette and distribute to project stakeholders. The report is intended to support the team in coming to consensus on goals, retrofit triggers, and the preliminary retrofit plan. Once finalized, it can be used as a basis for moving into the detailed analysis phase.

Download the Post-Read Template