Innovative heat recovery project for carbon emissions reduction

This case study was chosen as part of the Empire Building Challenge competition. Click here to learn more about the Empire Building Challenge competition.

Tags

Vornado Realty Trust is spearheading a groundbreaking retrofit at 1 Pennsylvania Plaza (PENN 1) in New York City, aiming to reach 100% carbon neutrality by 2040. This ambitious project is part of the company’s broader commitment to environmental sustainability, as outlined in their Vision 2030. PENN 1, a towering landmark in midtown Manhattan, stands at 57 stories and spans approximately 2.5 million square feet of office and retail space. Constructed in 1972, the building is a key component of THE PENN DISTRICT, Vornado’s flagship property cluster.

The roadmap to carbon neutrality at PENN 1 includes advanced waterside heat recovery measures. This strategy focuses on capturing and reusing heat from the building’s condenser water loop, a method that not only reduces heating loads but also facilitates a subsequent transition to electrification through air-source heat pumps and thermal storage. The PENN 1 project demonstrates a ‘thermal dispatch model,’ in which carbon-free energy sources are gradually deployed to fulfill the heating and cooling demands of a large commercial building.

By adopting this innovative approach, Vornado aims to significantly reduce the carbon footprint of PENN 1 while also setting a replicable model for building decarbonization in New York City. This initiative underscores Vornado’s role as a leader in sustainable real estate development, with a portfolio that includes over 34 million square feet of premier assets across New York City, Chicago, and San Francisco. Through Vision 2030, Vornado’s commitment to achieving carbon neutrality and a 50% site energy reduction reflects their dedication to pioneering sustainable solutions in the urban landscape.

Project Highlights

Step 1

Step 1: Examine Current Conditions

A baseline assessment is key to understanding current systems and performance, then identifying conditions, requirements or events that will trigger a decarbonization effort. The assessment looks across technical systems, asset strategy and sectoral factors.

Building System Conditions

- Equipment nearing end-of-life

- New heat source potential

- Tenant load change

- Resilience upgrades

- Efficiency improvements

Asset Conditions

- Repositioning

- Capital event cycles

- Carbon emissions limits

- Tenant sustainability demands

- Investor sustainability demands

Market Conditions

- Technology improves

- Policy changes

- Utility prices change

- Fuels phase out

The project team initially explored two packages of combined reduction measures to assess the impact of eliminating fossil fuels and electrifying the building’s heating end uses. Individual measures studied earlier in the project were selected and combined with additional infrastructure enhancements to develop two electrification packages summarized as follows:

- Beneficial Electrification: Incorporates a suite of tenant, airside, and envelope upgrades along with the installation of air source heat pumps working in conjunction with the cogeneration plant to keep the building heated; eliminates all district steam resources.

- Full Electrification: Incorporates the same set of upgrades but utilizes more air source heat pumps in place of the cogeneration plant.

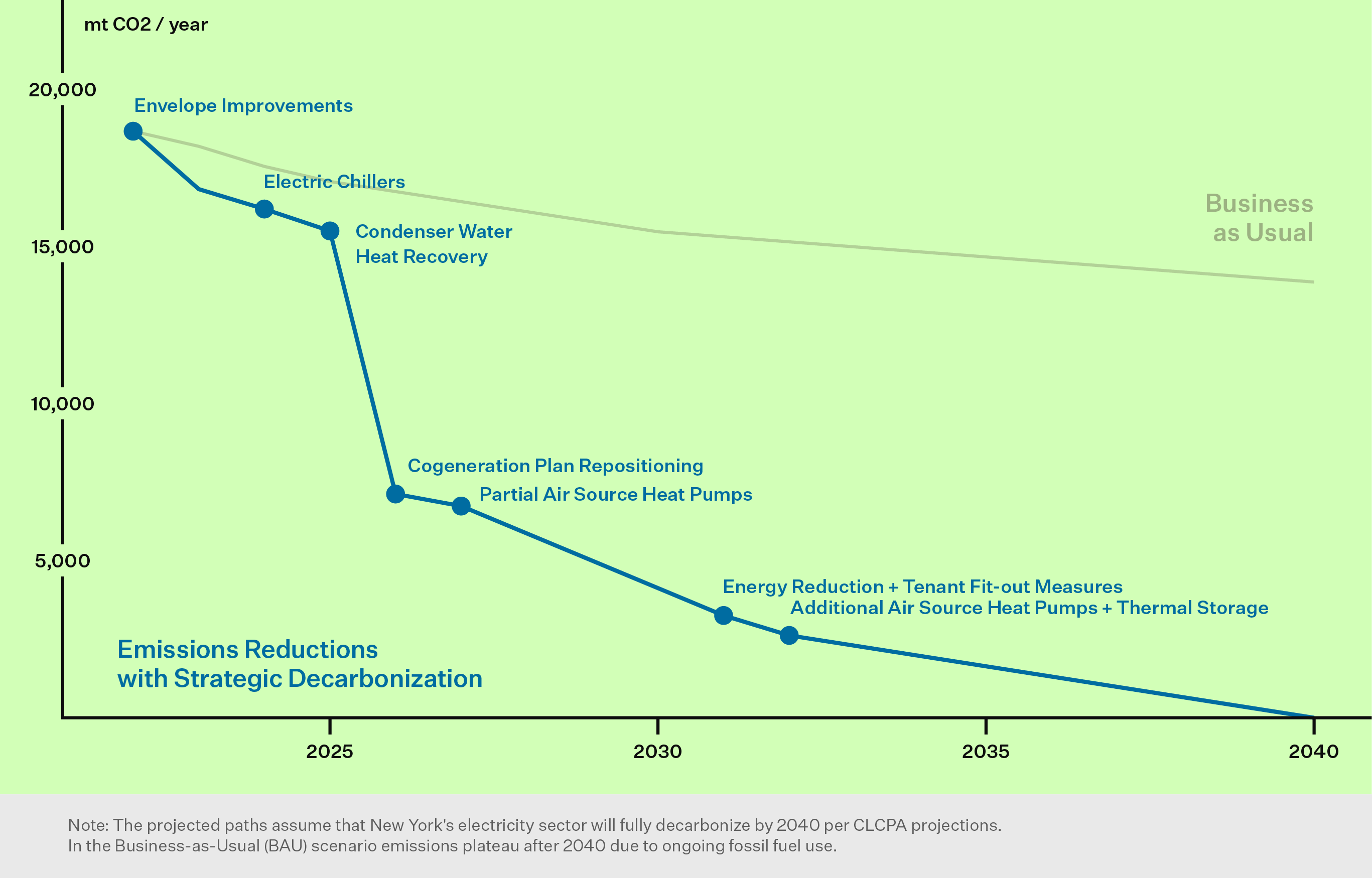

The thermal dispatch approach utilized at PENN 1 allows the building to intelligently prioritize low-carbon thermal resources for operational building needs ahead of those that are more carbon intensive. This strategy, enabled by electrification of heating loads and heat recovery measures, will reduce energy use by 22% and carbon emissions by 38% by 2030.

Step 2

Step 2: Design Resource Efficient Solutions

Effective engineering integrates measures for reducing energy load, recovering wasted heat, and moving towards partial or full electrification. This increases operational efficiencies, optimizes energy peaks, and avoids oversized heating systems, thus alleviating space constraints and minimizing the cost of retrofits to decarbonize the building over time.

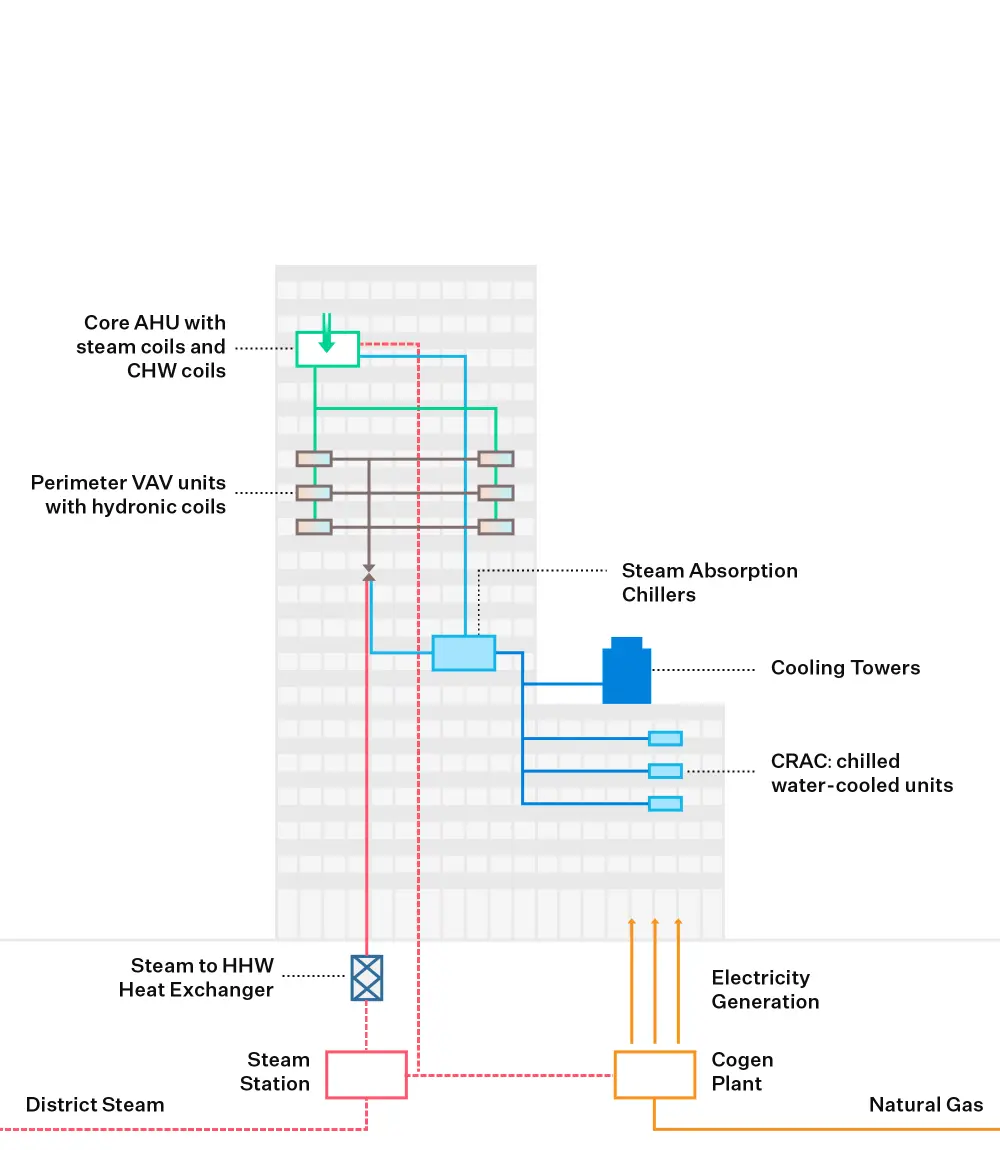

Existing Conditions

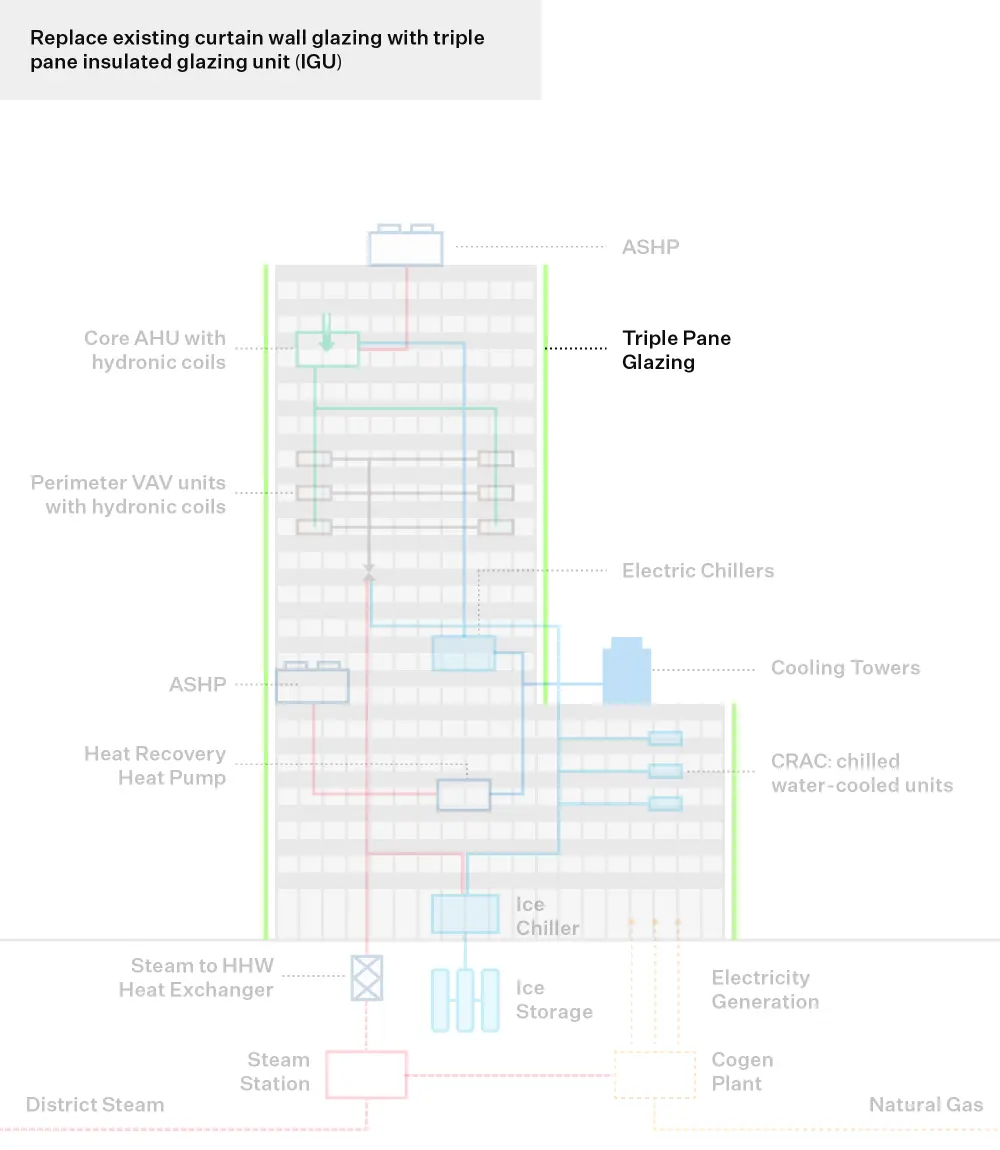

This diagram illustrates the building prior to the initiation of Strategic Decarbonization planning by the owners and their teams.

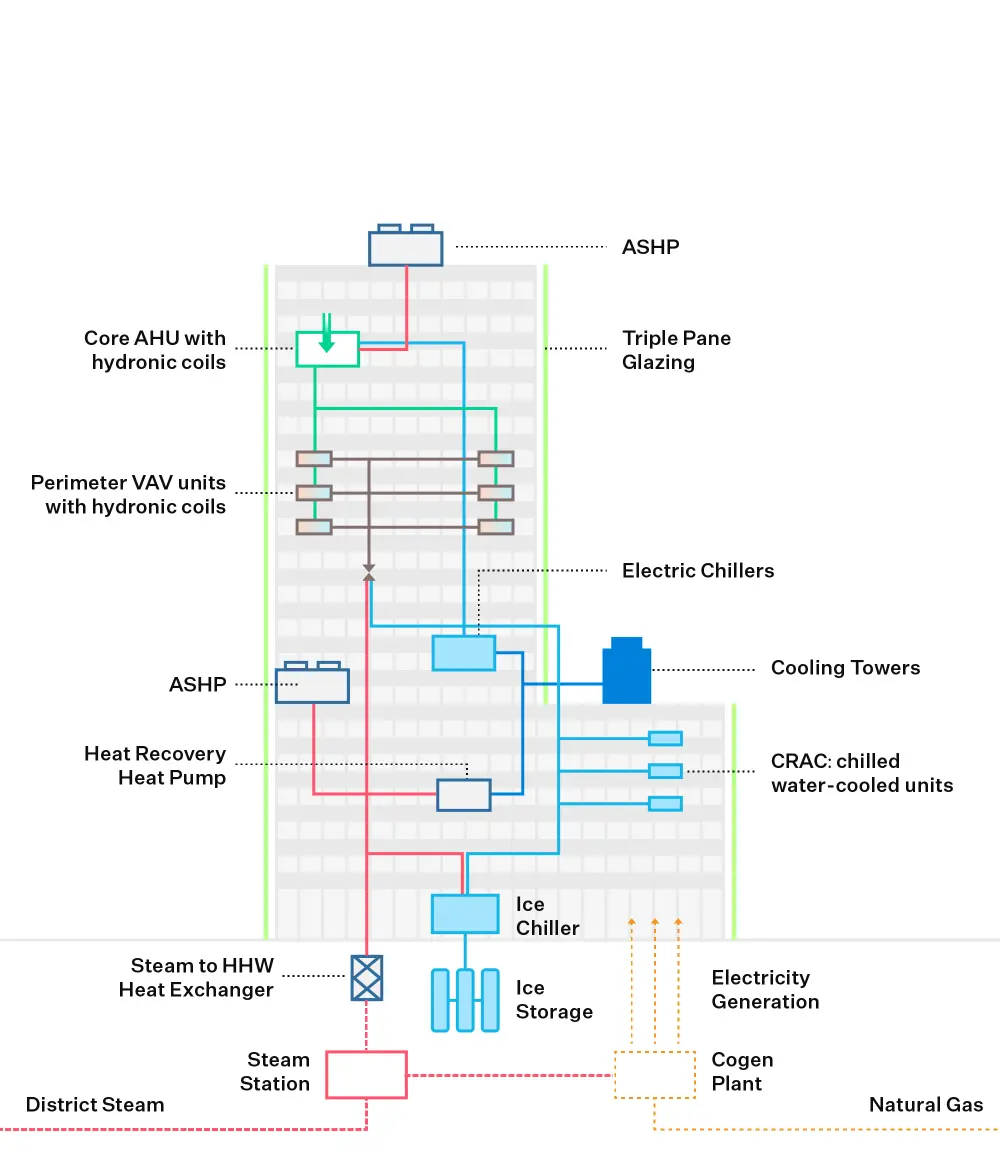

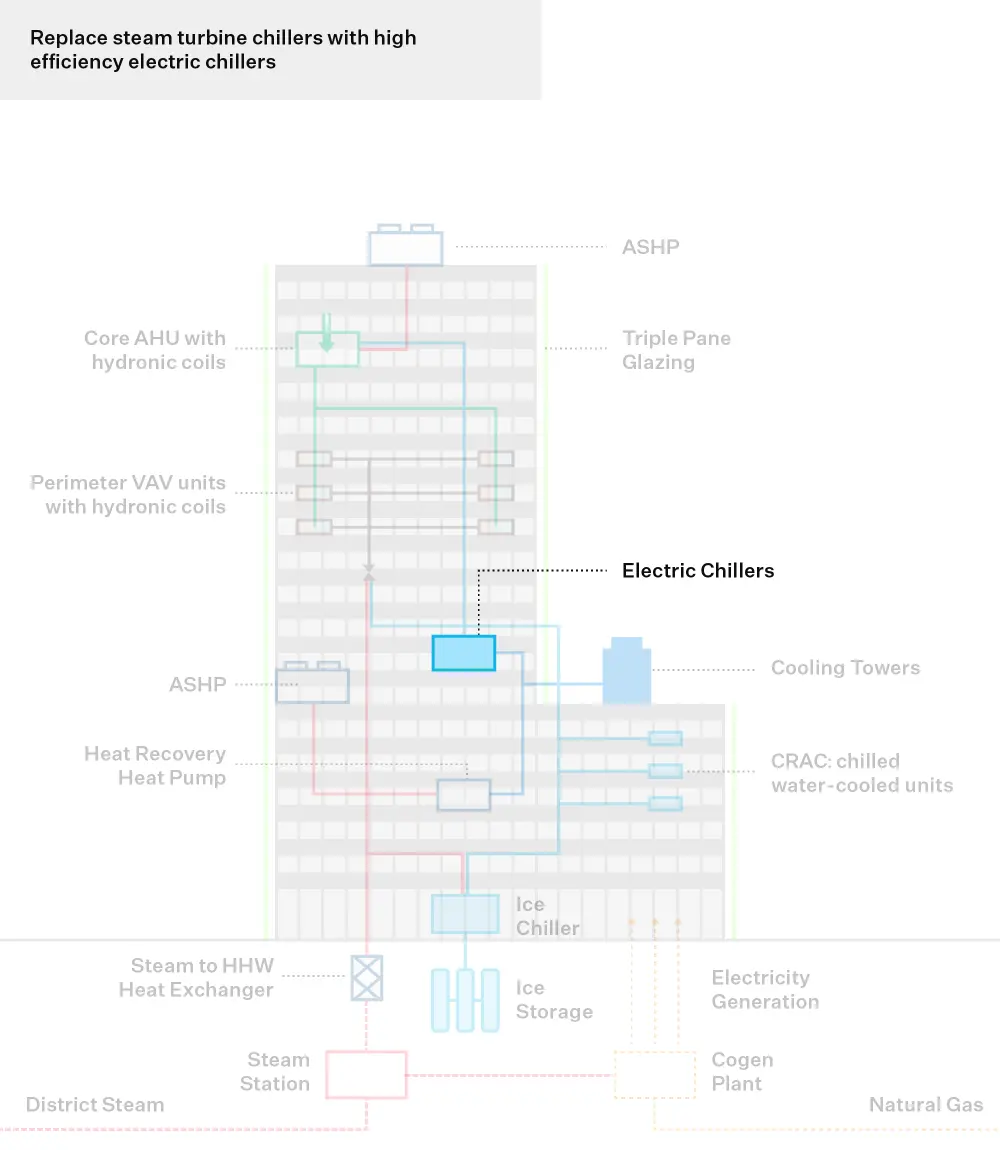

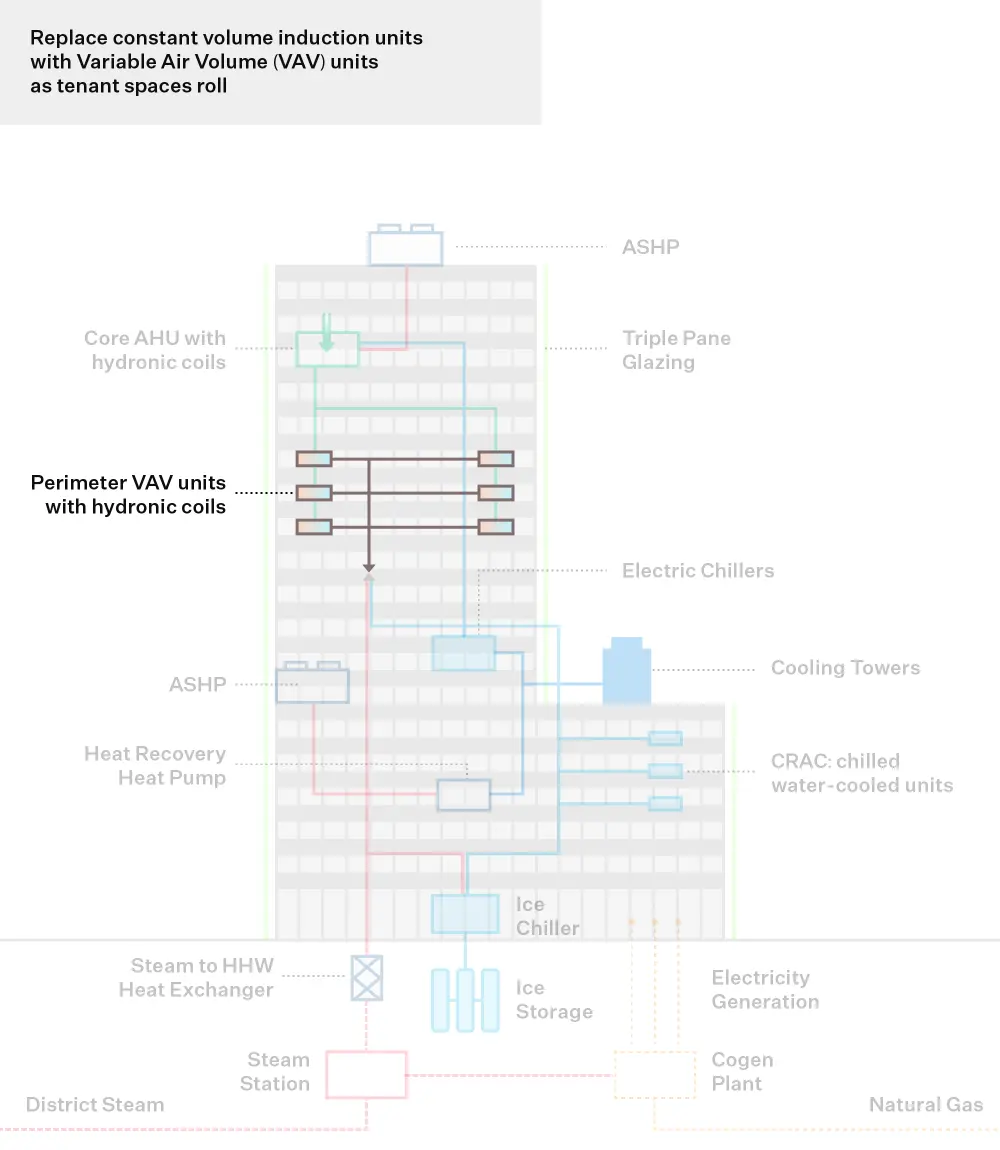

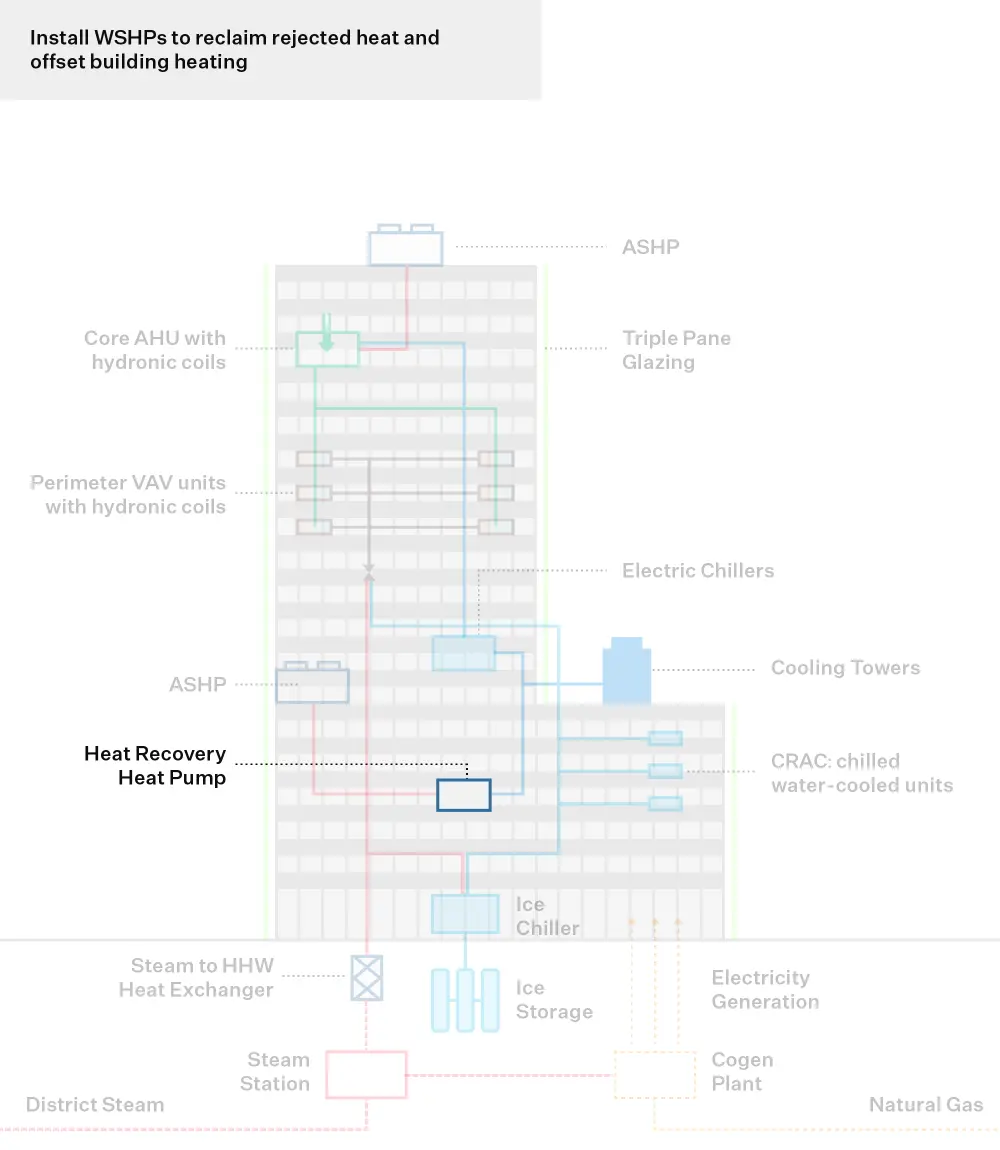

Click through the measures under “Building After” to understand the components of the building’s energy transition.

Sequence of Measures

2022

2023

2024

2025

2030

Building System Affected

- heating

- cooling

- ventilation

Reduce Energy Load

- Envelope Improvement: install new triple pane glazing

- Induction Units Replacement: replace constant volume perimeter induction units with VAV units

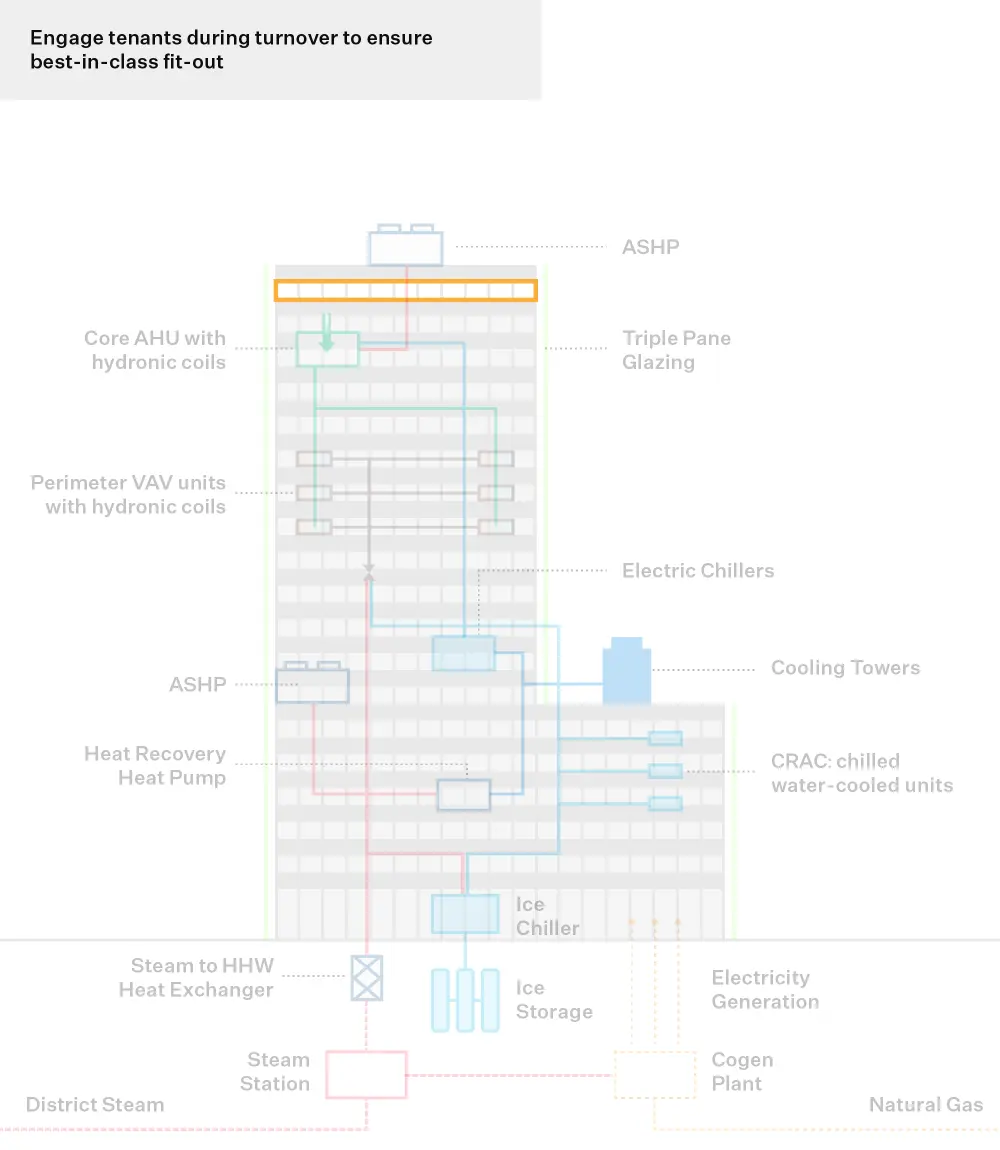

- Enhance Tenant Fit-out: Install high-efficiency equipment and engage with tenants to ensure best-in-class fit-out during turnover

- Thermal Layering: Heating loads are sequenced and prioritized to first engage low-carbon resources to meet the building’s heating demand, and then use next-available or higher carbon-intense thermal resources to come online. For example, first use low carbon electric thermal resources from water-source heat pumps, and then utility steam to meet remaining demand. When the ASHPs are installed, they will be dispatched second, as another low carbon alternative. This approach makes it possible to meet peak heating loads during extreme cold events with relative ease and low carbon emissions.

Recover Wasted Heat

- Condenser Water Heat Recovery: This tactic will use water-source heat pumps (WSHP) to utilize heat from the condenser water system to supplement heating hot water for the building’s hydronic system.

- The WSHP method creates a “heat-lifting” machine that will raise the temperature of hot water to match the building’s existing supply – usefully extracting heat that would otherwise be wasted and reducing steam heat emissions.

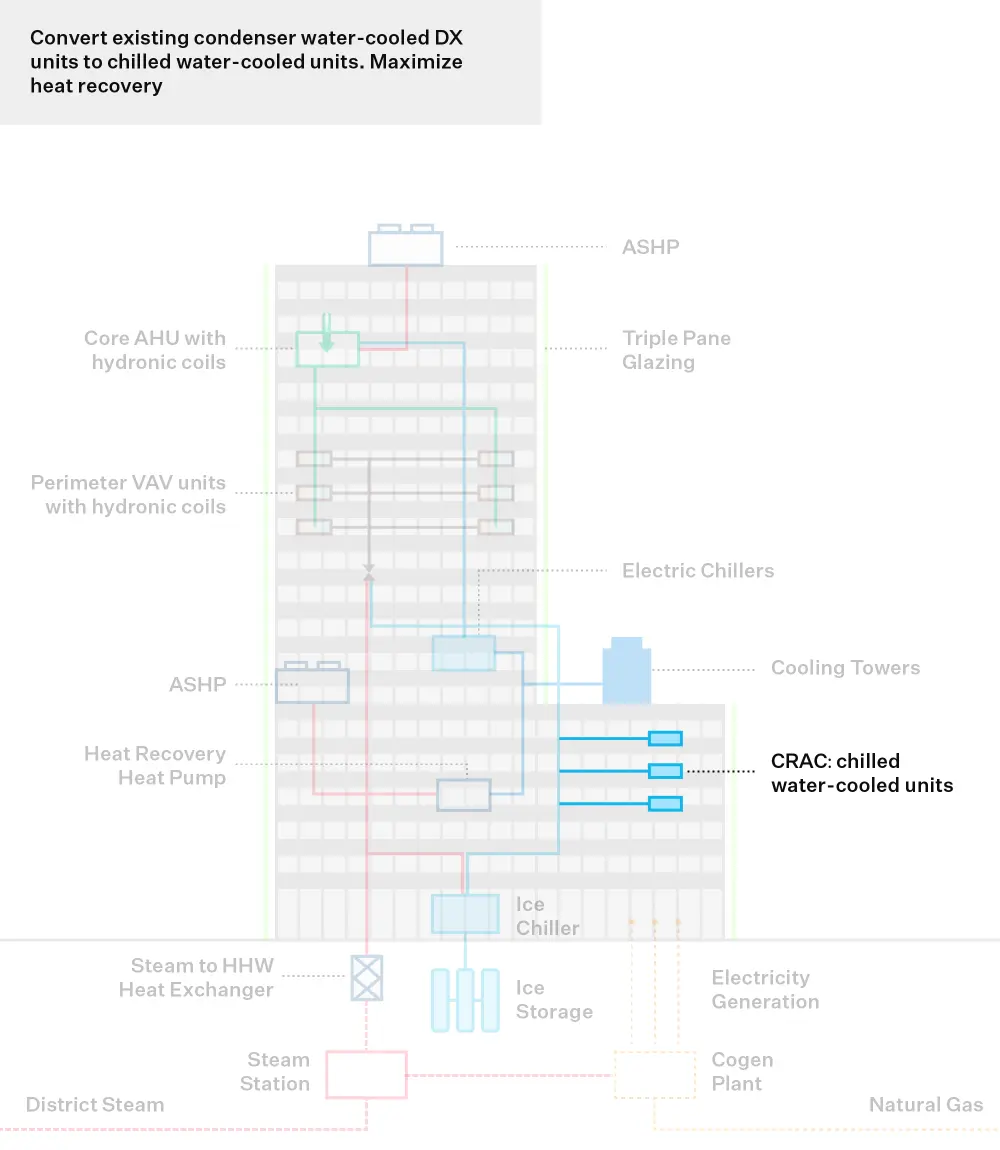

- Computer Room Air Conditioning (CRAC) Conversion: Convert existing condenser water cooled DX units to chilled water-cooled units to maximize heat recovery and improve cooling efficiency

Partial Electrification:

- Electric Chillers: Replace steam turbine chillers to electric chillers

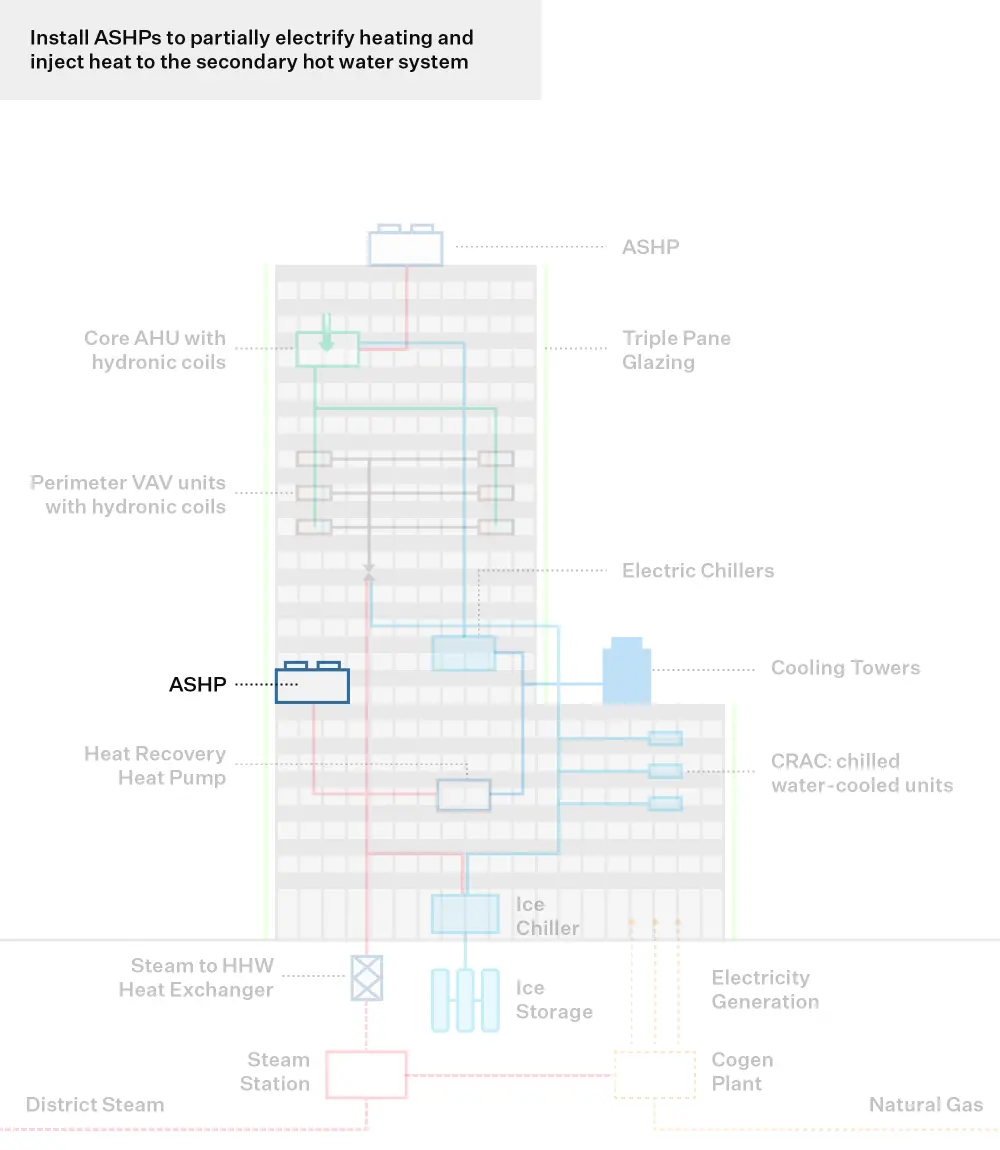

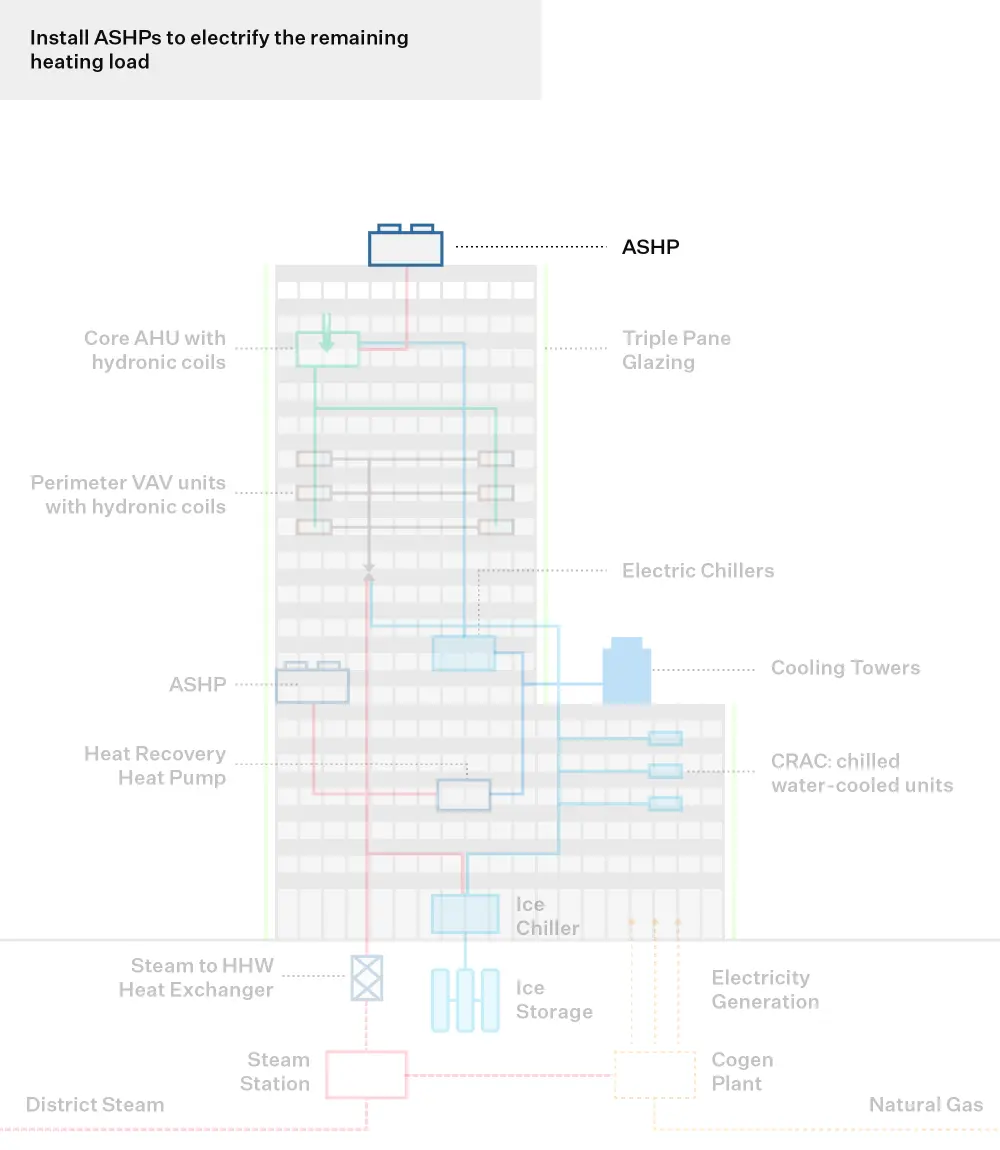

- Partial Air Source Heat Pumps: Install ASHPs to partially cover heating load served by the secondary hot water loop

Full Electrification:

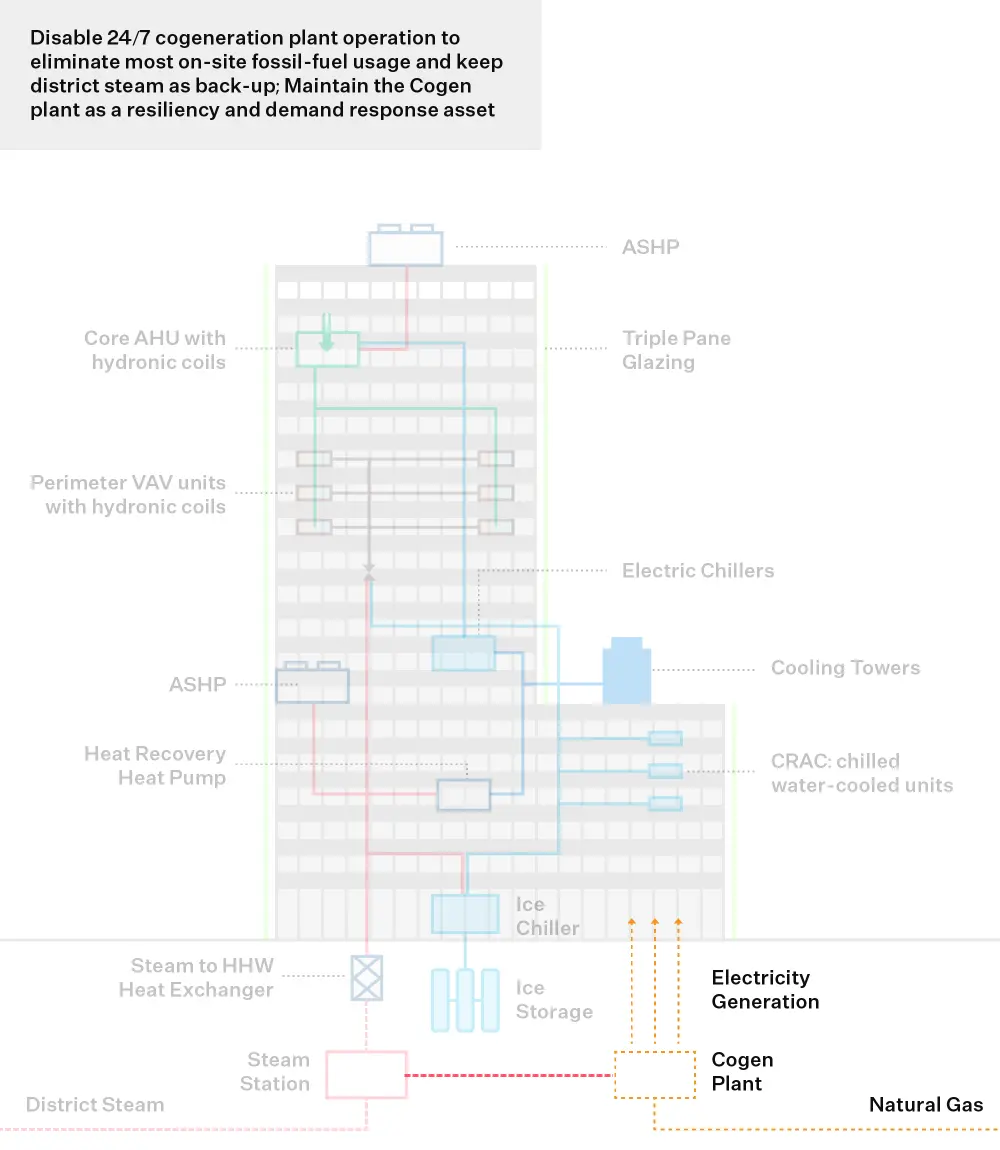

- Cogen Decommissioning: Retire cogeneration plant and eliminate on-site fossil fuel usage; keep district steam as back-up

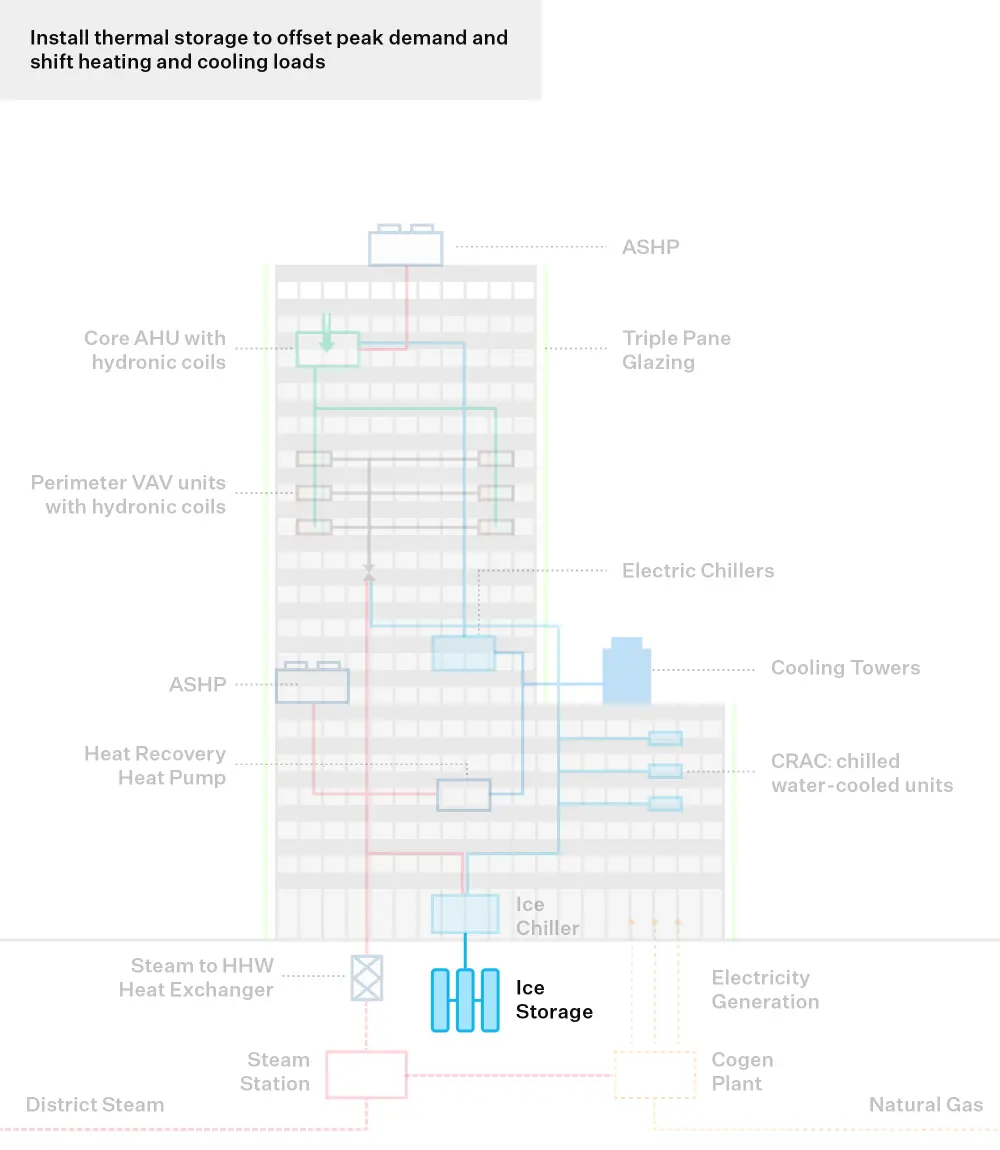

- Thermal Storage: Install thermal storage systems to enable full-building electrification by shifting and support heating and cooling peaks and empower grid flexibility

- More ASHPs: Install ASHPs to cover remaining heating load

Step 3

Step 3: Build the Business Case

Making a business case for strategic decarbonization requires thinking beyond a traditional energy audit approach or simple payback analysis. It assesses business-as-usual costs and risks against the costs and added value of phased decarbonization investments in the long-term.

Strategic Decarbonization Action Plan

An emissions decarbonization roadmap helps building owners visualize their future emissions reductions by outlining the CO2 reductions from selected energy conservation measures. This roadmap is designed with a phased approach, considering a 20- or 30-year timeline, and incorporates the evolving benefits of grid decarbonization, ensuring a comprehensive view of long-term environmental impact.

The Vornado team has gained countless lessons-learned on their decarbonization planning journey. The following are essential insights from the project team:

Insights from the energy model

The predictive energy model revealed that while the renovations to the building will yield significant energy and carbon reductions, the energy consumption from tenant spaces, such as computer and plug loads, must also be significantly reduced and intelligently managed to drive down the carbon intensity of the building (and reduce/eliminate exposure to LL97 through the 2030 compliance period).

While every effort was made to ensure that the model reflects the design team’s best understanding of the building’s existing conditions and future usage, the modeled energy consumption, energy cost, and carbon emission estimates will likely vary from the actual energy, cost, and carbon of the building after construction. This is due to variables such as weather, occupancy, building operation and maintenance, changes in energy rates, changes in carbon emission coefficients, and energy uses not covered by the modeling scope.

Underscoring the importance of an iterative design process

In the first iteration of the decarbonization strategy, the Vornado team approached the project with an all-or-nothing electrification mindset. They found that the strategies that achieve the deepest levels of decarbonization through fully eliminating district steam and co-generation waste heat as heating sources may not be practical nor cost efficient to implement in such a complex existing building. So, they went back to the drawing board.

In the second iteration of the project, a more holistic strategy emphasizing the following core principles was developed:

- Re-use existing infrastructure (i.e., piping and ductwork) where possible

- Recovery wasted heat from internal loads

- Electrify heating loads affordably with heat pumps

- Compress space requirements for electrification equipment/systems

- Dispatch thermally stored energy to shift and smooth loads to promote grid flexibility

Resource Efficient Electrification framework: With these guiding principles, the Vornado team developed a new strategy that follows the Resource Efficient Decarbonization Framework, which JB&B refers to as “Reduce, Recycle, Electrify”. Phasing, cost compression, and space compression were prioritized so that measures are more likely to be installed and scaled to other Vornado properties.

Key takeaways on the broader decarbonization decision-making process

- Invest in a Calibrated Energy Model – In large and complex buildings, building owners should commission a decarbonization study with an investment-grade calibrated energy model. Energy models should be custom built to the building’s unique characteristics, ensuring the analysis of retrofits are accurate and adds confidence to decision making. An energy model is a flexible tool that captures interactivity of all systems and ensures the strategies and measures studied have realistic energy and carbon reduction projections.

- Just Because It’s Feasible Doesn’t Mean It’s Practical – Anything is possible in an energy model. Technical teams must be aware that building ownership teams care about more than just the energy and carbon results from the model. Strategies must be practical in real-world scenarios and should aim to re-use existing infrastructure where possible, minimize disruption, use space efficiently, and compress costs as much as possible. Technical teams must be prepared to show building owners how a particular measure will be installed practically.

- Don’t Expect 5–7 Year Paybacks on Decarbonization Measures – Deep decarbonization measures will likely have long paybacks. This is due to high upfront costs of electrification technology, supporting infrastructure, and invasive retrofitting. Working against these high-efficient electric systems is the price of electricity, which is 5 to 6 times more expensive per unit of energy than natural gas. Simple payback analyses are unable to capture the true value of decarbonization investments, including non-energy benefits. Ownership teams have to adjust their payback expectations when considering deep decarbonization measures.

- Technological Innovation Isn’t the Only Innovation – There is new and exciting technology out there that has the potential to revolutionize the way we electrify buildings, but in the meantime, there are innovative approaches to electrifying buildings today with currently available technology. Purposeful dispatch of thermal energy sources and optimization for scalability, practicality, and affordability are innovative strategies.

- Conditioning Exhaust Air – Recycling waste heat from exhaust air streams isn’t a new idea, but using the refrigeration cycle to extract and lift heat from exhaust air streams to serve heating loads is a new and innovative concept. Essentially, by air conditioning the exhaust air, like traditionally avoided toilet exhaust, heat can be recovered and lifted to higher temperatures by a heat pump to offset heating loads. The reverse is also true in the summertime, where exhaust air can serve as a heat rejection medium for the chilled water production of chiller plants.

- Potential of Low Temperature Hot Water in Existing Chilled Water Coils – Low temperature hot water enables heat recovery and air source heat pumps to have a big impact, but reconfiguring all comfort heating systems in existing buildings to be low temperature is difficult and costly. The following approach offers a more practical alternative:

- Partially electrify high temperature hot water systems (i.e., perimeter systems) with water-source heat pumps and condenser heat recovery. This allows existing distribution infrastructure to stay in place – critical to wider spread of heat pump adoption.

- Transition air handling unit steam or hot water coils to low temperature, which can be served by air source heat pumps. The cost and scope of coil replacements is much more manageable than replacing all heating systems with low temperature hot water infrastructure. In some cases, existing chilled water coils can be used with low temperature hot water and become a modified change-over coil, negating the cost of replacement.

- Operations Team Integration: These decarbonization strategies are new and complex. Existing operations teams must be part of the design and implementation of these systems and training is of critical importance. A system that is designed to be low-carbon will not be successful if it is not operated per the design intent and understood thoroughly by those operating them.

- Disruption and Phasing: Some of the best decarbonization strategies are also some of the most disruptive. Phasing must be based upon several factors including the rate of grid decarbonization, leasing turnover cycles, capital planning cycles, and equipment nearing its end of useful life.